Wood Pellet Steam Boiler

Steam Boiler for Brewery

Suitable for various biomass fuels

Features

• Application for many industries, such as food&beverage/machinery/textile/papermaking industry, and other industries etc.

• Fuel: Biomass particles, rice rusk, palm shell, and wood chips etc.

• Rated steam capacity: 6t/h-15t/h(5,730HP-14.325HP)

• Rated Work Pressure: 12.5bar-25bar(181.30psi-362.60psi)

• Rated steam temperature: 194℃/204℃/225℃

• Core Control Mode:PLC control, PLC+PC control, DCS control

• Thermal Efficiency(%):>83%

Description

Reviews

Wood Pellet Steam Boiler Overview

Wood pellet steam boiler belongs to the SZL series boiler, it is a horizontal dual cylinder arranged, chain grating, pipe steam, designed by our technical personnel according to advanced technology and experiences from home and abroad. The technology, performance, and environmental protective index of this series of products reach the international advanced level, and this product is the mainstay in the boiler industry. This series of boilers absorbs the merits of the quick-fitting boiler, features with compact structure, the boiler's shop is story arranged, convenient for site installation, short in the construction period, cheap in cost, simple in operation, and etc. This series of wood pellet steam boiler is suitable for industrial and living steam consumption.

Wood pellet steam boiler is used in a steam boiler for brewery. It is one of the wood fired steam boiler for sale. Wood pellet steam boilers are used in the brewing industry, mainly to provide steam for distillation, disinfection, sterilization, and other processes in the production process. Our wood pellet steam boilers have the advantages of simple operation, good steam quality, energy saving, and environmental protection, and long service life. At the same time, wood pellet steam boiler is also used in the petroleum, chemical industry, chemical fiber, pharmaceutical, textile printing and dyeing, light industry, building materials, wood processing, food, road construction asphalt heating, and other industrial fields that require high temperature heating.

Wood Pellet Steam Boiler Technical parameter

| Wood Pellet Steam Boiler Technical Parameter | |||||

|

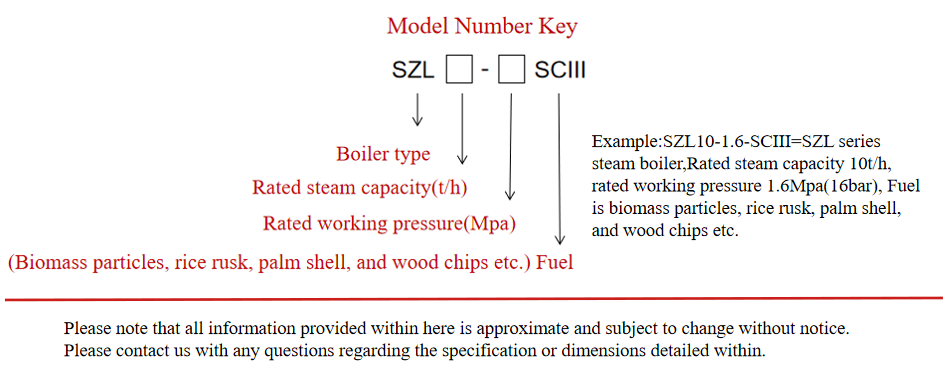

Model |

SZL6-1.25-SCIII | SZL8-1.25-SCIII | SZL10-1.25-SCIII | SZL12-1.25-SCIII | SZL15-1.25-SCIII |

| SZL6-1.6-SCIII | SZL8-1.6-SCIII | SZL10-1.6-SCIII | SZL12-1.6-SCIII | SZL15-1.6-SCIII | |

| SZL6-2.5-SCIII | SZL8-2.5-SCIII | SZL10-2.5-SCIII | SZL12-2.5-SCIII | SZL15-2.5-SCIII | |

| Rated steam capacity(t/h) | 6 | 8 | 10 | 12 | 15 |

| Rated working pressure(MPa) | 1.25/1.6/2.5 | ||||

| Rated steam temperature(℃) | 194/204/225 | ||||

| Feed water temperature(℃) | 20 | ||||

| Effective area of grate(㎡) | 6 | 8.81 | 11.86 | 13.7 | 16.5 |

| Thermal efficiency(%) | 83 | 83 | 83 | 86 | 86 |

| Applicable Fuel | Biomass particles, rice rusk, palm shell, and wood chips etc. | ||||

| Fuel consumption(kg/h) | 1303.6 | 1738.12 | 2172.66 | 2220.47 | 2698.82 |

| Max transport weight(t) | 23 | 26 | 29 | 36 | 28 |

| Max transport dimension LxWxH(m) | 7.0x2.7x3.5 | 7.0x3.2x3.5 | 8.3x3.4x3.5 | 8.7x3.4x3 | 9.4x3.4x3.6 |

| Control Range of control system by PLC Control, PLC+PC Control, or DCS Control | |||||

|

1) Control the frequency of the ID fan and FD fan: Automatically adjust the frequency of the ID fan according to the type of fuel and the amount of material to realize automatic air distribution to the boiler. 2) Control chain grate and fuel feeder: According to the calorific value of the fuel, the amount of materials and the energy consumption of the whole system,through the adjustment of the feeder and the grate,the boiler can be fully and efficiently burned,and the boiler load can be automatically adjusted. 3) Main control:temperature control,pressure control,liquid level control,auxiliary equipment control. 4) Monitor various parameters: The automatic control terminal monitors various operating parameters of the boiler in real time.If the set safety parameters are exceeded,the automatic control terminal will alarm and interlock for protection. 5) Provide one-button start-stop and optimized control for auxiliary equipment. |

|||||

Cabinets Type of Wood Pellet Steam Boiler Control System

Types of control cabinets for wood pellet steam boiler: wall-mounted control cabinet, podium control cabinet, MCC vertical control cabinet, piano-style control cabinet, positive pressure explosion-proof control cabinets, and three-proof control cabinet. Each control cabinet we leave the factory has a unique number, and it has the function of mobile phone viewing. You can see the operating status of the boiler in real-time, such as temperature, water level, pressure, alarm record, etc. But the actual operation still needs to be completed by the staff in the boiler room. The control cabinets picture is shown as follows:

Wood Pellet Steam Boiler Features

| Wood Pellet Steam Boiler Features | Function |

| Extreme low water level electrode (steam boiler) | · Except for the water level safety setting of international regulation, we add extremely low water level electrode protection. The electrode interlocks with the FD fan and ID fan to make sure the water level is safe when the biomass boiler is operating. |

| Independent air bin |

· Set different quantities of independent air bin from front to rear grate according to different steam capacity; · Distribute air reasonably according to various fuel and combustion conditions to make sure that the fuel is totally fired. |

| Panel |

· Cold rolling pressed film forms concave-convex panel which has great rigidity, strength, and beauty. · Fixed by self-tapping screw and there is no welding spot. · After the rust is removed, the surface will be printed with corrosion prevention, finishing coat, and primer. |

| Chain grate | · Chain grate layer burning, scientific furnace, reasonable air distribution, full combustion of pellets fuel. |

| Spring full lift safety valve |

· The safety valve discharge capacity is calculated strictly; · When the system pressure exceeds the rated value, the safety valve will open decompression automatically to make sure that no accident would occur because of high system pressure. |

| Secondary air inlet |

· Disturb the furnace flue gas to ensure the total combustion of volatile matters. · Air volume makes up 30% of total air volume. The airspeed is around 50m/s · Air volume and air pressure of separate secondary fan is easy to be controlled and adjusted. |

Company Profile

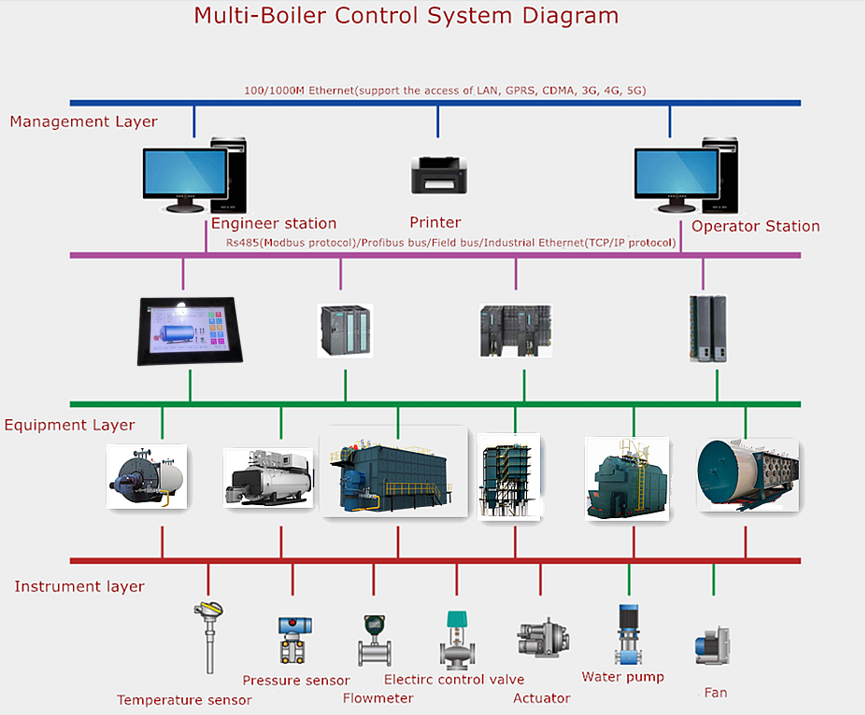

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeter, electric control valve, Zirconia, TDS sewage, and so on.

CN Boiler has always adhered to the concept of electrical full integration in the industrial energy industry, that is, integrating strong and weak current systems such as boiler control, boiler room auxiliary machine control, upper monitoring system, and boiler room power distribution system into a complete electrical package, forming a characteristic industrial energy control system (CN Boiler Multi-Boiler Control System, referred to as CN Boiler- MBCS). The control system is shown as follow:

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed