Temperature Controller K Type Thermocouple

High Temp K Type Thermocouple

Well-sold,Cost-effective products

Features

• Small diameter/unlimited length/high precision/reducing dynamic error

• Material: stainless steel

• Measurement temperature range: -200℃~600℃

• Temperature-sensing element material: Pt

• Type: k type thermocouple

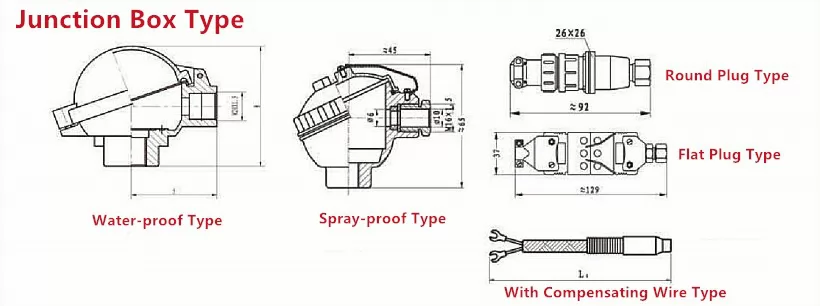

• Junction box type: water-proof type, spray-proof type, round plug type, flat plug type, with compensating wire type

• Min. order: 1 piece

• Customization

Introduction

Reviews

Temperature Controller K Type Thermocouple Overview

In the industrial production process, temperature is one of the important parameters that need to be measured and controlled. In temperature measurement, Temperature controller K type thermocouple is widely used. It has many advantages such as simple structure, convenient manufacture, wide measurement range, high precision, small inertia, and easy remote transmission of the output signal. In addition, because temperature controller k type thermocouple is an active sensor, it does not need an external power supply for measurement, and it is very convenient to use, so temperature controller k type thermocouple is often used to measure the temperature of the gas or liquid in the furnace, the pipeline, and the surface temperature of the solid.

Temperature Controller K Type Thermocouple is one of the most prevalent high temperature K type temperature thermocouple, that is, Pt100 thread temperature sensor. Also commonly referred to as PT100/PT1000, its resulting popularity is due to its accuracy and response, at temperatures between -200℃ to +600℃.

According to the national regulations, our company’s fabricated thermocouples, meet the IEC international standard graduation number Pt100 platinum thermocouple.

Temperature Controller K Type Thermocouple Main Parameter

| Temperature Controller K Type Thermocouple Main Technical Parameters | ||||||||

| Executive standard | IEC60751, JB/T30121-2013 | |||||||

| Junction box type | Water-proof type, Spray-proof type, Round plug type, Flat plug type, With compensating wire type | |||||||

| Wiring Method | Single Wiring Method, Double branch wiring method | |||||||

| Material in the Diameter of Thermocouple Wire | Thermal Response Time | |||||||

| Thermocouple wire type | Single support | Double support | Casing diameter/mm | Φ3 | Φ4 | Φ5 | Φ6 | Φ8 |

| Casing diameter | Φ3, Φ4, Φ5, Φ6, Φ8 | Φ4, Φ5, Φ6, Φ8 | Thermal response time/s | ≤3 | ≤5 | ≤8 | ≤12 | ≤15 |

| Casing material | 1Cr18Ni9Ti | 1Cr18Ni9Ti | ||||||

| Temperature-sensing Element Parameter | ||||||||

| Name | Model | Graduation | Range of temperature measurement | Specification(L) | ||||

| Single thermocouple | WZP-101 | Pt100 | A class, -30℃ ~ 300℃ | 310, 360, 410, 460, 510, 560 | ||||

| Double thermocouple | WZP2-101 | Pt100 | B class, -50℃ ~ 500℃ | 310, 360, 410, 460, 510, 560 | ||||

| Measuring Range&Tolerance Deviation | ||||||||

| Graduation | Tolerance level | Wire wound element measuring range | Membrane element measuring range | Tolerance Deviation ℃ | ||||

| Pt100 | AA | -50℃ ~ 250℃ | 0℃ ~ 150℃ | ±(0.1+0.0017|t|) | ||||

| Pt100 | A | -100℃~ 450℃ | -30℃ ~ 300℃ | ±(0.15+0.002|t|) | ||||

| Pt100 | B | -196℃ ~ 600℃ | -50℃ ~ 500℃ | ±(0.3+0.005|t|) | ||||

| Pt100 | C | -196℃ ~ 600℃ | -50℃ ~ 600℃ | ±(0.6+0.01|t|) | ||||

Temperature Controller K Type Thermocouple Classification

· According to the structure, Temperature Controller K Type Thermocouple can be divided into K type armored thermocouple, and K type explosion-proof thermocouple;

· According to the logarithm, RTD Type Thermocouple can be divided into single, double;

· According to the purpose, there are thermocouples for vacuum, high temperature wear-resistant thermocouples, and so on.

· According to the fixation mode, Temperature Controller K Type Thermocouple can be divided into Non-fixing device temperature sensor, Fixed-sleeve screw thread temperature sensor, Active-sleeve screw thread temperature sensor, Fixed-sleeve flange temperature sensor, Active-sleeve flange temperature sensor.

Temperature Controller K Type Thermocouple Features

◒ With the quick thermal response, reduce dynamic error

◒ Small diameter, unlimited length

◒ High measuring accuracy

◒ Import thin-film resistance element, stable performance

Temperature Controller K Type Thermocouple Structure

Temperature Controller K Type Thermocouple is mainly composed of a junction box, a protective tube, an insulating sleeve, a wire terminal, a thermal electrode, a compensation wire, and several main fixing devices for installation. The compensation wire is a special wire used for signal transmission between the thermocouple and the secondary (base) instrument, which can eliminate the measurement error caused by the temperature change of the cold junction of the thermocouple and ensure the accurate measurement of the medium temperature by the instrument.

Temperature Controller K Type Thermocouple Working Principle

It is based on the theory that material temperature change results in resistance value change to measure material temperature. when the thermal resistance value changes, the instrument will display the relevant temperature.

Junction box type: water-proof type, spray-proof type, round plug type, flat plug type, with compensating wire type. The temperature controller k type thermocouple junctions box connection is as follows

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeters, electric control valves, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed