Steam Mass Flow Meter

Pulse Output Dosing Flow Meter

Features

• Single-circuit digital display controller provides easy operation with a measurement precision of 0.3%;

• Measurement of industrial process quantifiers including temperature, pressure, flow, liquid level, humidity etc.

• Standard MODBUS protocol, 1-way DC24V feed output; photoelectric isolation between input, output

• Supporting 2-way alarm, 1way control output or RS485 communication interface adopting

• Support Communication protocol: 1200n1, 2400n1, 4800n1, 9600n1

• Measurement temperature range: 100°C~320°C

• Type: turbine flowmeter

Description

Reviews

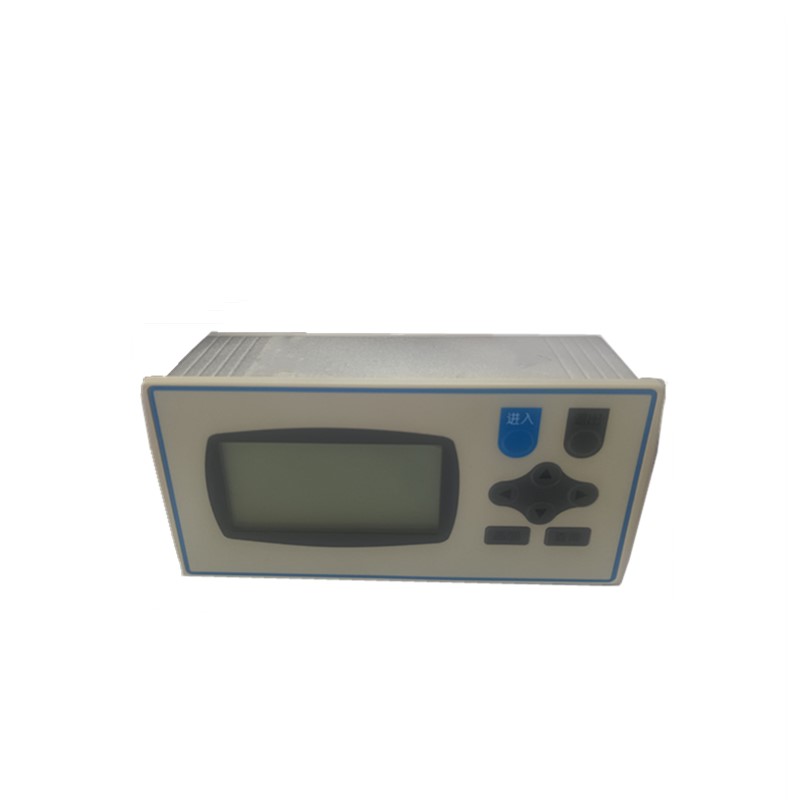

Steam Mass Flow Meter Overview

The flow totalizer collects, displays, controls, remote transmission, communication, printing, and other processing for various signals such as temperature, pressure, and flow on-site, and constitutes a digital acquisition system and control system. The steam mass flow meter has a liquid crystal and digital display, and various dimensions, suitable for flow integration measurement and control of various liquids, general gases, superheated steam, and saturated steam; quantitative/batch control of media (with start, stop, and zeroing functions), and various flow sensors or transmitters. The steam mass flow meter can be used in conjunction with the controller and can adapt to various measurement and control occasions. The flow totalizer is used in conjunction with various flow sensors or transmitters, temperature sensors or transmitters, and pressure transmitters to measure, display, accumulate, and calculate flow parameters for various liquids, steam, natural gas, and general gases. Alarm control, transmission output, data acquisition, and communication.

The steam mass flow meter is sometimes referred to as a flow meter or flow totalizer. The flow totalizer meter displays the flow rate from either an analog or pulse output flow sensor as well as the accumulated total and grand total volume over time. Flow meters are devices used to measure the flow rate or quantity of a gas or liquid in a pipe. The pulse output dosing flow meter works on the basis of a flow sensor. It shows the data results that people want.

The steam mass flow meter is suitable for measurement, display, control, and metering integration of tap water, oil, liquid, solid fluid, and other industrial process flow parameters that do not need to be compensated. It can receive orifice plate differential pressure input or input signals of various flowmeters such as vortex flowmeters, electromagnetic flowmeters, turbine flowmeters, etc.

Steam Mass Flow Meter Features

★ Full-range automatic temperature and pressure compensation calculation, and the compensation method can be set arbitrarily;

★ Linear integration and square root integration can be set arbitrarily;

★ Various parameters display instantaneous flow, cumulative flow, temperature, and pressure;

★ Small signal cut-off function, the cut-off range is 0-5% optional;

★ The cumulative flow value can be reset by the panel buttons, and the reset operation

★ Power-down protection function, the accumulated flow value is kept for more than 5 years after power-off, and all set values are permanently maintained after power-off

★ Received with various flow sensors or transmitters, temperature sensors or transmitters,

Steam Mass Flow Meter Technical Specification

| Steam Mass Flow Meter Technical Parameter | |

| Product name | Flow totalizer |

| Flow input signal | Frequency signal:0~5000Hz, V 低 ≤ 1V,V 高 ≥ 5V; III model signal: 4~20mA |

| Temperature input signal | Pt100: 100~320℃, III model signal: 4~20mA |

| Flow output signal | III model signal: 4~20mA |

| Density range of superheated steam | Pressure:0~26.55MPa,temperature:100~320℃ |

| Accuracy | Accuracy of flow temperature and pressure compensation < ±0.3% |

| Supply power | AC: 85V~260V DC: 24V; Max consumption:5W |

| Output power | +12V: 12V/50 mA +24V: 24V/50mA |

| Dielectric strength |

Dielectric strength of power supply to ground 1500VAC1 minute The insulation strength of the power supply to the shell is greater than 1500VAC for 1 minute |

| Relay alarm | 3A_30V/DC 1A_125V/AC |

| Display | LCD display, operating ambient temperature range: -20°C~ 70°C |

| Button | 6 buttons |

| Communication interface |

The standard configuration provides RS-485 communication interface for users to choose. Up to 255 units can be connected |

| Communication protocol | 1200n1, 2400n1, 4800n1, 9600n1 |

| Weight | 0.5kg |

| Dimensions | 160×80×65mm |

Steam Mass Flow Meter Working Principle

The steam mass flow meter is composed of four parts: measurement loop, digital panel meter, regulator, and power supply. The stabilized power supply converts the 220V power supply into a stable DC voltage as the other part of the power supply. The measurement loop processes the signal (voltage, current, etc.) sent by the flow transmitter into a voltage signal. After A/D conversion, the signal is sent to a dedicated central processing unit for processing. Not only to the digital panel meter but also to the regulator. After comparing with the set value, it outputs a control or alarm signal according to the regulation rule.

"Flow totalizer" simple control totalizer has strong anti-interference, intuitive display of LED color interface, can directly receive 4-20mA signal, 0-5V, 0-10V, pulse signal, etc. It has a temperature compensation port and pressure compensation port, can be configured with Modbus-485 communication protocol, and can exchange information with DCS, PLC, and other control terminals, The flow totalizer is a commonly used paperless recorder.

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeters, electric control valves, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed