Steam Boiler Control Panel

IPT3 Oil Boiler Control Panel

Cheaper! Cheaper! Cheaper!

Features

Core control hardware: PLC

HMI(Human Machine Interface): 10-inch true color touch screen

Control product appearance: Wall-mounted Cabinet | Podium Cabinet | MCC Vertical Cabinet | GGD Vertical Cabinet |Piano console

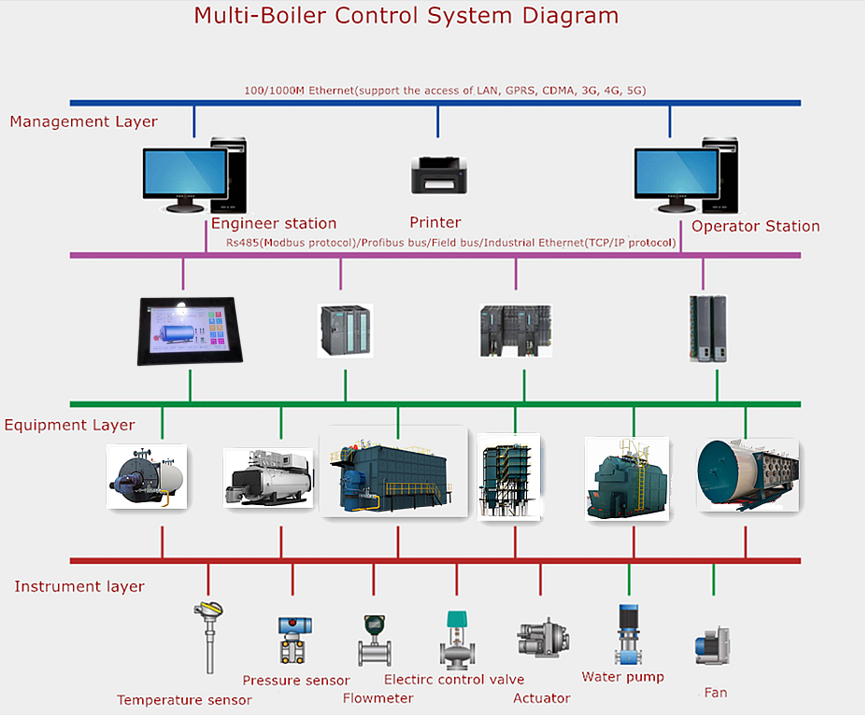

Main communication interface: Ethernet | Connect RS-485 communication interface through DTU to realize networking

Boiler capacity range: 0.5T/H-35T/H

Application: Steam boiler | hot water boiler | vacuum boiler | thermal oil boiler | hot air boiler etc.

Description

Reviews

Overview of the Steam Boiler Control Panel

The steam boiler control panel can be used for oil fired steam boilers, gas fired steam boiler, coal fired steam boiler, biomass fired steam boiler, electric steam boiler, and other boiler types. Relying on the experience of many technicians in the control of industrial boilers, the steam boiler control panel is designed and manufactured according to industrial standards for the special use environment of boilers, with high anti-interference performance. Various boiler intelligent control software modules are built-in, which can be flexibly configured into a high-performance boiler control system and networked control.The boiler control panel has 20 kinds modes to meet various types of the boilers. The steam boiler control panel has 25 kinds modes to meet various types of the boilers.

CN Boiler has always adhered to the concept of electrical full integration in the industrial energy industry, that is, integrating strong and weak current systems such as boiler control, boiler room auxiliary machine control, upper monitoring system, and boiler room power distribution system into a complete electrical package, forming a characteristic industrial energy control system (CN Boiler Multi-Boiler Control System, referred to as CN Boiler- MBCS). As the main power source of industrial enterprises, steam boilers are widely used in various fields of industrial processes, such as metallurgy, chemical industry, machinery, papermaking, medicine, food light industry and so on. In recent years, the number of applications of gas-fired steam boilers in industrial processes has increased significantly.

Steam Boiler Control Panel Advantages:

★ High integration, scalability, and low cost of comprehensive control system configuration.

★ Microcontroller PLC design, with touch screen management module, which is beneficial to control costs and facilitate installation and use.

★ The IO capability can be expanded according to the type and capacity of the equipment to be controlled by the analog module of the switch module, and the lower cost can meet the control requirements

Steam Boiler Control Panel Technical Parameter

| Product features | |

| Screen | 10" true color touch screen,resolution 1024x600 |

| Display color | 65535 colour |

| Backlight lifespan | 50,000 hours |

| Touch screen | Resistive |

| Power supply | 24V DC |

| CPU motherboard | ARM low power consumption,400MHz |

| Memory | 32M SDRAM |

| Storage device | 128M FLASH |

| Product specification | |

| Structure | industrial plastic structure |

| Colour | Industrial black |

| Panel size | 282mm×190mm |

| Cabinet opening hole size | 274mm×182mm |

| Net weight | 0.9kg |

| External interface | |

| Interface RS-485 | Modbus slave protocol+Modbus slave protocol/Analog switch expansion module host protocol |

| USB | 1 Host, 1 Slave |

| Ethernet | RJ45 Ethernet interface |

| Environment | |

| Working temperature | 0℃~45℃ |

| Working humidity | 10%~90% |

| Protection | |

| Protection class | IP65 |

| Anti-interference | Industrial protection class III |

Steam Boiler Control Panel Technical Features

• Anti-crash:

In extreme cases, even if the main CPU crashes or is broken, the self-control terminal can reliably cut off the equipment control.

• Heat source contact protection:

In extreme cases, such as heat source contact adhesion, the system will start a redundant protection mechanism

• Transmitter short circuit protection:

When the transmitter is short-circuited, the sampling circuit has a self-protection mechanism to avoid damage caused by over-voltage.

• CPU & Components:

32-bit ARM series, high speed. High electromagnetic compatibility performance, and stronger anti-interference ability. The main components are all international brands such as ST, ON, and T. The relay adopts high stability Taiwan Songchuan series.

• Water quality adaptability:

The liquid level measurement system can adapt to large-scale conductivity.

• HMI(Human Machine Interface):

High-stability industrial-grade true-color touch screen, wide field of view and clear observation from multiple angles, industrial-grade waterproof and anti-fouling capacitive touch buttons.

• Communication Interface:

Standard 485 interface, multiple units can be used in parallel and can be networked with the central computer room to realize automatic control and remote monitoring.

• Control Panel:

Made of acrylic polymer material with hardened surface for excellent weather resistance.

• Machine shell:

Using PC flame retardant material, it has extremely high strength and toughness.

Company profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeter, electric control valve, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed