Saving Energy Waste Heat Boiler

Waste Heat Recovery Boiler

Customized products

features

· Working pressure: ≤ 11 Mpa (1595.418psi)

· Rated steam capacity: 1t/h-20t/h(955HP-19,100HP)

· Rated thermal power: 0.7MW-14MW(955HP-19,100HP)

· Control core: PLC, PLC+PC, DCS

· Application field: Smelting, Chemical industry, Building materials, Papermaking, Solid waste

· Customization of product, design patent

Introduction

Reviews

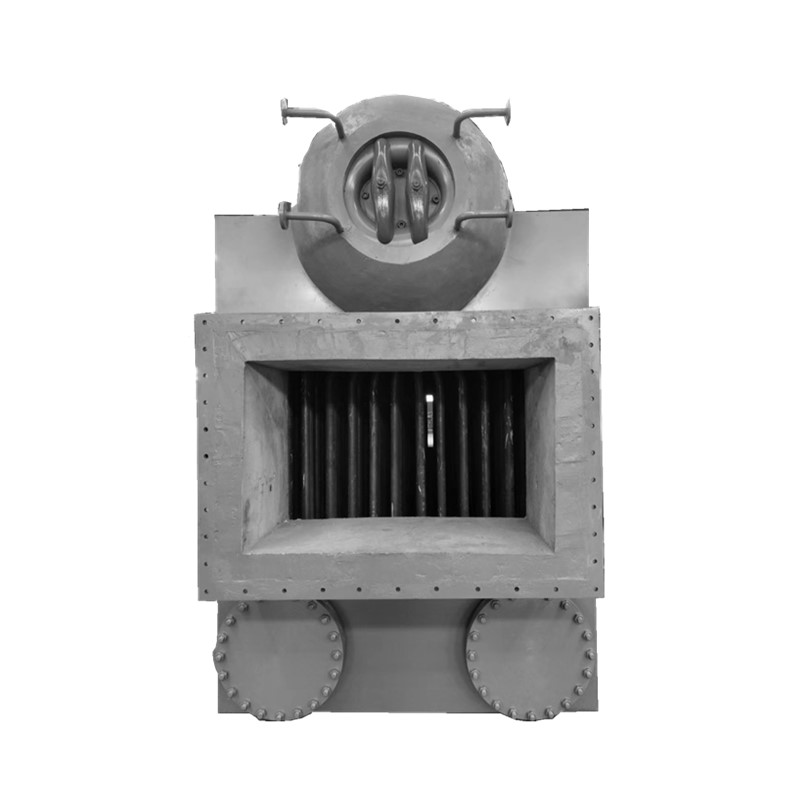

Overview of the waste heat boiler

A waste heat boiler is a waste recovery boiler that uses the waste heat in the waste gas, waste material, or waste liquid in various industrial processes and the heat generated by the combustion of combustible substances to heat the water to a certain temperature. The waste heat boiler can produce hot water or steam through waste heat recovery to supply other production processes. Since the waste heat boiler greatly improves the utilization rate of the heat released by fuel combustion, so waste heat boiler is very energy-saving.

Structure of the waste heat boiler

The waste heat boiler consists of a drum, a movable hood, a flue at the furnace mouth section and other flues, a feeding pipe (feeding chute) groove, an oxygen gun mouth, a nitrogen sealing device, and a nitrogen sealing plug, an inlet hole, and a differential pressure taking device, Flue support and hanger and other components.

Design thought of the waste heat boiler

The flue gas temperature entering the waste heat boiler is an important factor in determining the layout of the heating surface of the waste heat boiler. If the inlet flue gas temperature is about 220-900℃, the boiler is mainly equipped with convection tube bundles, and no furnace chamber is installed. However, there are exceptions when the melting point of smoke and dust is low. A cooling furnace room should be set up to control the temperature of the inlet smoke entering the convection flue, so as to prevent ash from bridging between the convection pipe rows.

The waste heat boiler is a customized product. We can understand some specific issues according to your actual situation, such as where the waste heat comes from, the flow rate of flue gas, temperature and composition analysis report, whether you want to steam or hot water, etc., combined with our actual experience. Let our engineers design a waste heat boiler that fits your industry standard.

Features of the waste heat boiler

★ The overall heating surface of the boiler adopts a suspended structure, which is conducive to absorbing the expansion of the boiler and has high operating safety.

★ The boiler adopts a special sealing device to reduce the air leakage of the boiler and improve the thermal efficiency of the boiler

★ Each heating surface of the boiler adopts a reasonable smoke velocity design, which is beneficial to prevent dust accumulation

★ The boiler is arranged in a straight cylinder, which can use the dust's own weight for self-cleaning, which can keep the heating surface clean and improve the heat transfer rate of the boiler

★ The boiler rationally organizes the flue gas dynamic field to make the flue gas flow smoothly and evenly, avoiding bias flow. At the same time, it adopts a special anti-wear structure, which is beneficial to prevent boiler wear and prolong the life of the boiler.

★ Boiler convection tube bundle adopts an assembly structure, which has a short installation period and low cost. At the same time, the vertical waste heat boiler has the advantages of a small footprint, low civil construction investment, high heat exchange efficiency, and strong self-dust removal ability.

Category of the waste heat boiler

According to the nature of waste heat, it can be divided into the following categories:

A) High temperature flue gas waste heat boiler: It is a common form, which is characterized by large output, concentrated production points, strong continuity, and easy recycling and utilization.

B) High temperature slag waste heat boiler: Such as blast furnace slag, converter slag, electric furnace slag, etc., the temperature of the slag is above 1000 ℃, and the heat it takes away accounts for 20% of the total heat.

C) High temperature product waste heat boiler: Such as coke in coke ovens, steel ingots, billets, high-temperature forgings, etc., which generally have a high temperature and contain a lot of waste heat.

D) Waste heat boiler for combustible waste gas and waste liquid: Such as blast furnace gas, catalytic cracking waste gas from refineries, black liquor from paper mills, etc., can all be utilized.

E) Chemical reaction waste heat boiler: Such as metallurgy, sulfuric acid, phosphoric acid, chemical fertilizer, chemical fiber, paint, and other industrial sectors, all produce a large amount of chemical reaction waste heat.

F) Cooling medium waste heat boiler: for example, a large amount of cooling water discharged from cooling devices such as water jackets of industrial furnaces, and steam produced by various vaporization cooling devices contain a large amount of waste heat, which can be used reasonably.

G) Condensate waste heat boiler: The physical sensible heat of steam used in the production process of various industrial sectors when it condenses and decreases after the industrial process.

System of the waste heat boiler

★ The waste heat boiler main body and primary valve instrument

★ Water system: The water system refers to the water provided to the boiler for steam or hot water conversion for use in other processes

Control system of the waste heat boiler

The boiler control system is a collection of boiler electrical control components, a center for collecting and processing boiler operating signals, and an operation platform for sending execution instructions to each execution unit of the boiler.

For waste heat boilers, our control core control methods: are PLC control (programmable), PLC+PC control, and DCS control, the screen interface is as follows:

Types of control cabinets for waste heat boilers: wall-mounted control cabinet, podium control cabinet, MCC vertical control cabinet, piano-style control cabinet, positive pressure explosion-proof control cabinets, and three-proof control cabinet.

Each control cabinet left the factory has a unique number, and it has the function of mobile phone viewing. You can see the operating status of the boiler in real-time, such as temperature, water level, pressure, alarm record, etc., but the actual operation still needs to be completed by the staff in the boiler room.

Functions of the waste heat boiler's control system

★ Real-time monitoring function, real-time monitoring of combustion system and steam-water system, and interlocking in case of abnormality, while the circulation system runs continuously to ensure safe and stable production.

★ Self-inspection function of the control system: temperature, pressure, liquid level, and other sensor fault self-inspection, internal fault self-inspection of the control device, fault alarm, and interlock protection.

★ Real-time analysis function for waste heat boiler operation.

★ Collect, record, save, and manage important information and data functions related to the system.

Control principle: Through the real-time data collection, monitoring, and processing of boiler water level, pressure, smoke temperature, and flow, the purpose of intelligent and safe operation is achieved.

Control content: pressure, temperature, liquid level and flue gas temperature, fault alarm, and interlock, etc.

The Remote Instrument Valves used in the control system include temperature sensors, pressure transmitters, pressure controllers, flow-meter, etc.

Boiler Control Modes of Operation: Automatic and Manual

a) The boiler in automatic mode is in a fully automatic operation state,

b) Manual mode: The operation of the boiler equipment is controlled by manual operation. Under normal circumstances, the boiler should operate in an automatic operation state. In special cases, it will be required to switch to the manual state.

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators (electric steam generators, electric hot water generator), intelligent control systems by PLC control, PLC+PC control or DCS control, remote instrument and valves and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed