RTD Type Thermocouple

Platinum Thermocouple

Features

• Spring thermal element with good shock-proof/Wide measuring range/High precision

• Material: stainless steel

• Measurement temperature range: -200℃~500℃

• Type: RTD-Type

• Wiring Mothed: Single Wiring Method, Double branch wiring method

• Min. order: 1 piece

• Customization

Introduction

Reviews

RTD Type Thermocouple Overview

An RTD type thermocouple (Resistance Temperature Detector or Resistance Temperature Device) is one of the most prevalent RTD type temperature sensors used in industry today. Also commonly referred to as PT100/PT1000, its resulting popularity is due to its accuracy and response, at temperatures between -200℃ to +500℃.

Industrial RTD type thermocouple is used as a measuring temperature sensor. It is usually used with instruments, recorders, and electronic regulators. It can directly measure or control liquid, vapor, and the temperature of the surface of gaseous media and solids, in various production processes from -200°C to +500℃.

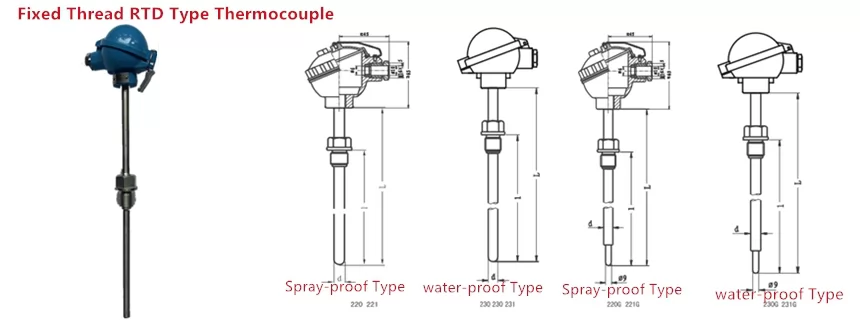

According to the national regulations, our company’s fabricated thermocouples, meet the IEC international standard graduation number Pt100 platinum thermal resistance, and the professional standard graduation number Cu50 copper thermal resistance, two types of assembly, unified design type thermal resistance. If you need another size, we can customize it for you. According to the connection method, RTD type thermocouple can be divided into RTD Type thermocouple without fixing device, fixed thread type RTD Type thermocouple, movable flange type RTD Type thermocouple, fixed thread conical RTD Type thermocouple, flexible pipe joint type RTD Type thermocouple, and straight pipe joint type RTD Type thermocouple, and fixed threaded pipe joint type RTD Type thermocouple, the following is an example of fixed threaded RTD Type thermocouple, the specific product parameters are as follows:

| Fixed Thread RTD Type Thermocouple Parameter | |||||

| Type | Graduation | Measuring Range | thermal response time | Specification | |

| d/mm | L*I/mm | ||||

| WZP-220 | PT100 | -200℃ ~+500℃ | <90s | φ16 |

300x150 350x200 400x250 450x300 500x350 550x400 650x500 900x750 1150x1000 1650x1500 2150x2000 |

| WZP2-220 | |||||

| WZP-220G | PT100 | -200℃ ~+500℃ | <24s<90s<90s | φ16 | |

| WZP2-220G | |||||

| WZP-221 | PT100 | -200℃ ~+500℃ | <90s<24s<90s<90s<24s<90s | φ12 | |

| WZP2-221 | |||||

| WZP-221G | PT100 | -200℃ ~+500℃ | <24s<90s<24s<90s<90s<24s<90s<90s<24s<90s | φ12 | |

| WZP2-221G | |||||

| WZP-230 | PT100 | -200℃ ~+500℃ | <90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s | φ16 | |

| WZP2-230 | |||||

| WZP-230G | PT100 | -200℃ ~+500℃ | <24s<90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s | φ16 | |

| WZP2-230G | |||||

| WZP-231 | PT100 | -200℃ ~+500℃ | <90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s | φ12 | |

| WZP2-231 | |||||

| WZP-231G | PT100 | -200℃ ~+500℃ | <24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s | φ12 | |

| WZP2-231G | |||||

| WZC-220 | Cu50, Cu100 | -50℃ ~+100℃ | <120s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s | φ16 | |

| WZC-220G | Cu50, Cu100 | -50℃ ~+100℃ | <40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<120s<24s<90s<24s<90s<24s<90s<24s<90s | φ16 | |

| WZC-230 | Cu50, Cu100 | -50℃ ~+100℃ | <120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<120s<24s<90s<24s<90s<24s<90s<24s<90s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s | φ16 | |

| WZC-230G | Cu50, Cu100 | -50℃ ~+100℃ | <40s<120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<120s<24s<90s<24s<90s<24s<90s<24s<90s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s | φ16 | |

| WZC-221 | Cu50, Cu100 | -50℃ ~+100℃ | <120s<40s<120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<120s<24s<90s<24s<90s<24s<90s<24s<90s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<40s<120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s | φ12 | |

| WZC-221G | Cu50, Cu100 | -50℃ ~+100℃ | <40s<120s<40s<120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<24s<90s<120s<24s<90s<24s<90s<24s<90s<24s<90s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<40s<120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s<120s<40s<120s<40s<120s<24s<90s<24s<90s<24s<90s<24s<90s | ||