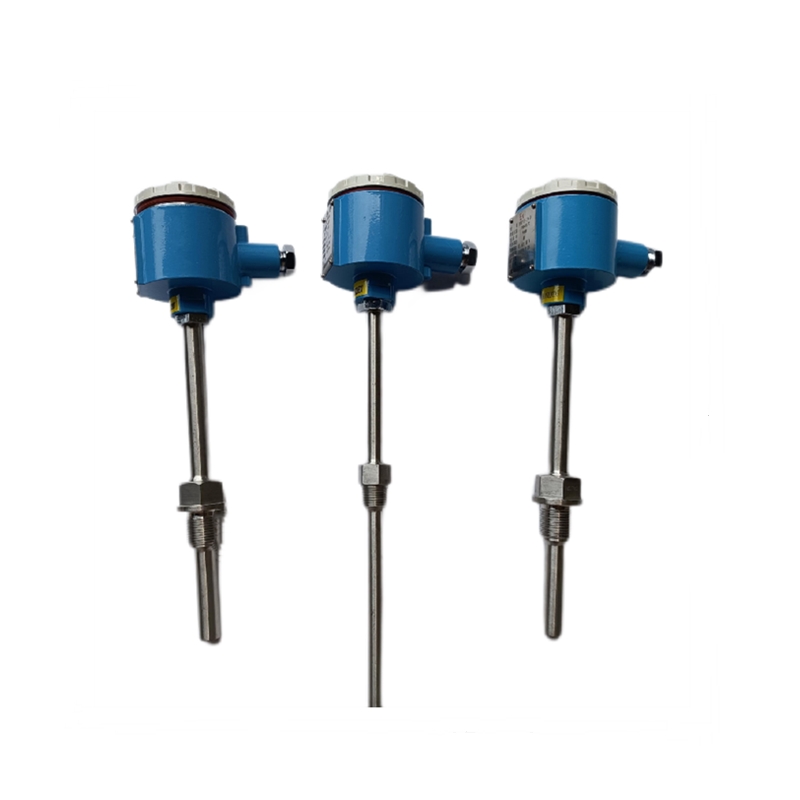

PT100 Explosion Proof Thermocouple

Isolated Thermocouple

Best selling, High performance cost

Features

• Explosion proof/Wide measuring range/high precision/reducing dynamic error

• Material: stainless steel

• Measurement temperature range: -200℃~500℃

• Type: boiler temperature sensor

• Junction box type: CT type, BT type

• Min. order: 1 piece

• Customization

Introduction

Reviews

PT100 Explosion Proof Thermocouple Overview

PT100 explosion proof thermocouple is suitable for measuring boiler water temperature and smoke temperature, at the same time,it is a commonly used temperature measuring element in temperature measuring instruments. PT100 explosion proof thermocouple directly measures the temperature and converts the temperature signal into a thermal electromotive force signal, and converts it into the temperature of the measured medium through an electrical instrument (secondary instrument). The shapes of various thermocouples are often very different due to needs, but their basic structures are roughly the same, usually composed of main parts such as thermal electrodes, insulating sleeve protection tubes, and junction boxes, and are usually associated with display instruments, recording instruments, and electronic regulators used together with the device to directly measure the temperature of liquid, vapor, gas and solid surface ranging from -200℃ to 500℃ during various production process. According to the connection method, pt100 explosion-proof thermocouples(WZP series thermocouple) can be divided into fixed thread thermocouples, fixed flange thermocouples, flexible pipe joint thermocouples, straight pipe joint thermocouples, and fixed thread pipe joint thermocouples.

In the industrial production process, temperature is one of the important parameters that need to be measured and controlled. In temperature measurement, pt100 explosion proof thermocouple is widely used. It has many advantages such as simple structure, convenient manufacture, wide measurement range, high precision, small inertia, and easy remote transmission of the output signal. In addition, because the explosion proof thermocouple is an active sensor, it does not need an external power supply for measurement, and it is very convenient to use, so it is often used to measure the temperature of the gas or liquid in the furnace, the pipeline, and the surface temperature of the solid.

PT100 Explosion Proof Thermocouple Grouping Method

| Explosion-proof Class under Electrical Equipment in the plant | |

| Class | Maximum experimental safety gap (MESG) mm |

| A | 0.9≤MESG |

| B | 0.5<MESG<0.9 |

| C | MESG≤0.5 |

| Temperature Class of PT100 Explosion Proof Thermocouple | |

| Class | Allowable maximum surface temperature ℃ |

| T1 | 450 |

| T2 | 300 |

| T3 | 200 |

| T4 | 135 |

| T5 | 100 |

| T6 | 85 |

| Protection class | IP65 |

Thermocouple Classification

· According to the structure, it can be divided into assembly thermocouple, armored thermocouple, and explosion-proof thermocouple;

· According to thermoelectric characteristics, there are 2 standardized graduation numbers and other non-standardized thermocouples with special purposes; such as K type thermocouple (WZPK), C type thermocouple (WZC).

· According to the logarithm, it can be divided into single, double, and multiple thermocouples;

· According to the electrode resource status, there are noble metal thermocouples and base metal thermocouples;

· According to the purpose, there are thermocouples for vacuum, high temperature wear-resistant thermocouples, and so on.

· Thermocouple product names generally contain various classification meanings such as structural features, graduation numbers, and logarithms, such as explosion-proof K-type double-branched thermocouples.

PT100 Explosion Proof Thermocouple Feature

◒ Various explosion-proof types, good explosion-proof performance

◒ Spring thermal element with good shock-proof

◒ Wide measuring range, high precision

◒ High mechanical strength, good press-resistant performance

◒ Simple structure, convenient manufacture, small inertia, and easy remote transmission of the output signal

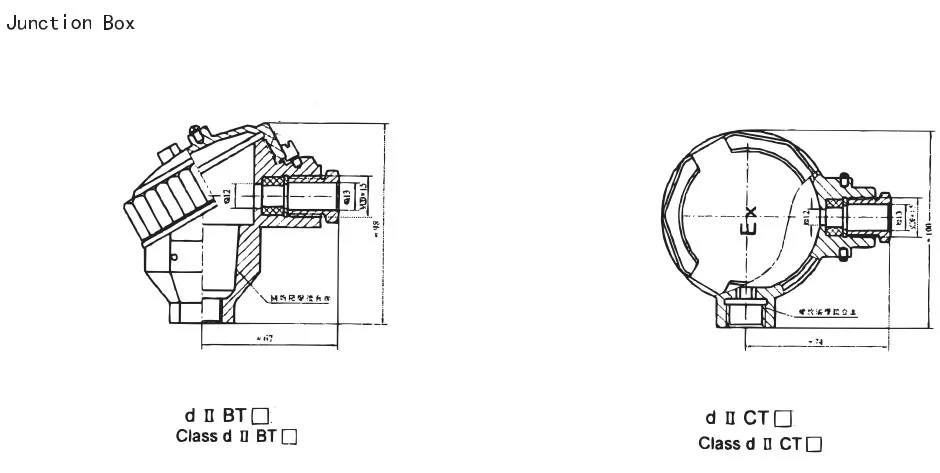

PT100 Explosion Proof Thermocouple Structure

The PT100 Explosion Proof Thermocouple is mainly composed of a junction box, a protective tube, an insulating sleeve, a wire terminal, a thermal electrode, a compensation wire, and several main fixing devices for installation. The compensation wire is a special wire used for signal transmission between the thermocouple and the secondary (base) instrument, which can eliminate the measurement error caused by the temperature change of the cold junction of the thermocouple and ensure the accurate measurement of the medium temperature by the instrument.

PT100 Explosion Proof Thermocouple Working principle

The PT100 explosion proof thermocouple is designed with sufficient strength by using the principle of gap explosion-proof. Junction boxes and other components are all parts that can generate sparks, arcs, and dangerous temperatures. The components are sealed in the junction box cavity, when the explosion occurs in the cavity, it can pass through the joint surface. The gap is extinguished and cooled so that the flame and temperature after the explosion cannot pass out of the cavity, so that flameproof.

Junction box type: CT type, BT type. The PT100 explosion proof thermocouple junctions box connection is as follows

Company profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeters, electric control valves, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed