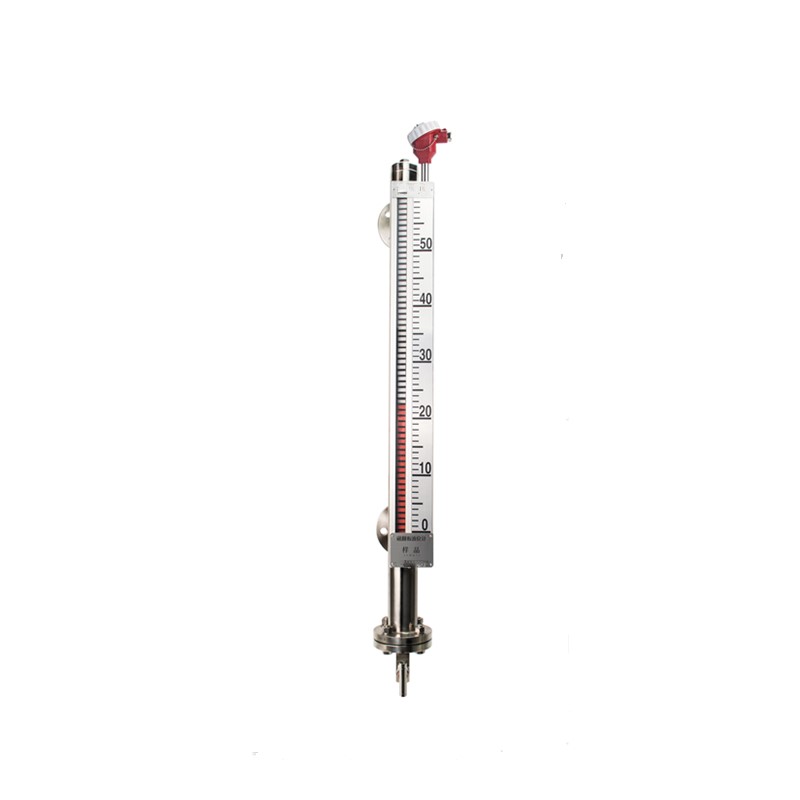

Magnetic Float Level Gauge

Magnetic Liquid Level Gauge

High accuracy, Large measuring range

Features

• High accuracy/Large measuring range/High sealing/Leakage prevention/No blind area/Upper and lower limit switch output

• Magnetic flap liquid level gauge structure

• Medium density: 0.5-2.0g/cm3

• Working pressure: ≤4.2MPa(42Bar)

• Installation center distance L: 300/350/440/600/800/1000/1200/1500/1800/2000/2400/2800/3000mm

• Connection flange caliber: DN20~DN50

• Flange material: SUS304,SUS316L

• Working temperature: -40℃~350℃

• Output signal: 4-20mA

Introduction

Reviews

Magnetic Float Level Gauge Overview

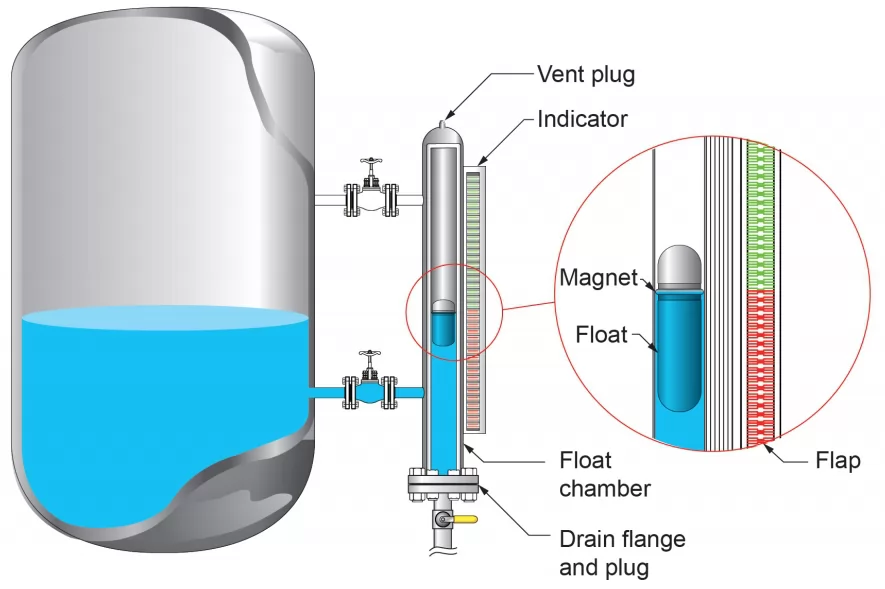

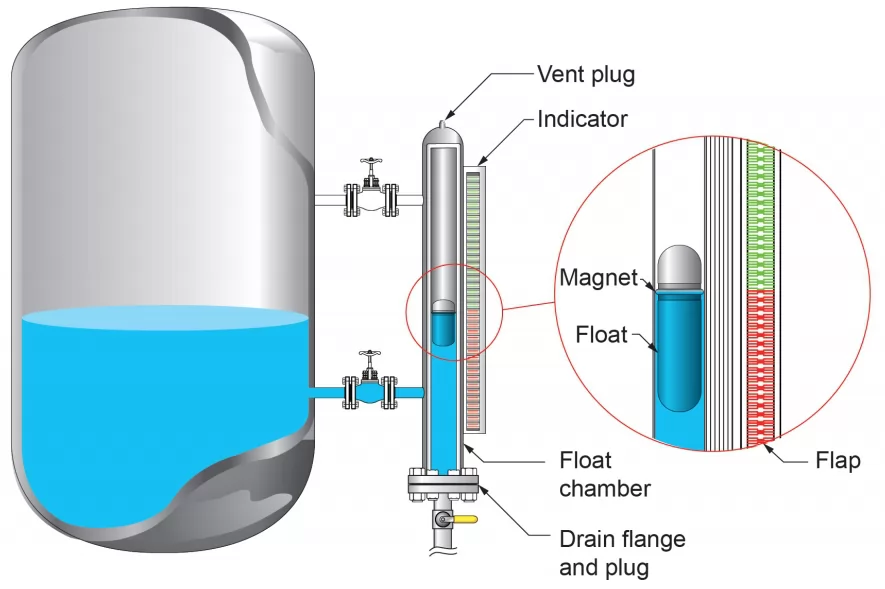

The magnetic float level gauge is installed on the extension pipe outside the tank, and the liquid level inside the tank can be clearly known from the indicator on the flap. A magnetic switch can also be installed on the outside of the bypass pipe as an electrical contact signal output, or a liquid level transmitter can be installed for long-distance liquid level signal transmission and liquid level control. The magnetic float type level gauge is a reliable and safe instrument. Due to its magnetic coupling isolation and closed structure, it is especially suitable for flammable, explosive and corrosive and toxic liquid level detection, so that the liquid level detection method in the original complex environment becomes simple, reliable, and safety. The magnetic float level gauge has the direct-reading characteristic of local display, does not require multiple sets of liquid level gauges, and has the advantages of full-scale measurement by a single unit, fewer openings for equipment, clear display, eye-catching signs, and intuitive readings. When the magnetic float level gauge is directly equipped with a display device, the intermediate transmission of the signal detection of the system can be omitted, thereby improving its transmission accuracy. The magnetic level sensor can be used for medium liquid level detection of various towers, tanks, groove, spherical containers and boilers and other equipment.

The magnetic float level gauge is widely used in liquid level measurement and control in the production process of electric power, petroleum, chemical industry, metallurgy, environmental protection, shipbuilding, construction, food and other industries.

Magnetic Float Level Gauge Structural features

★ Magnetic flap liquid level gauge structure

According to the buoyancy principle of the liquid level gauge, the float moves up and down with the rise and fall of the liquid level in the measuring tube. The permanent magnet steel in the float drives the red and white turning columns to turn over 180' through magnetic coupling. When the liquid level rises, the turning columns turn from white to white. It is red, and when it falls, the turning column turns from red to white, so as to realize the indication of liquid level.

★ Upper and lower limit switch output

Use the magnetic float to move with the liquid level to make the reed switch installed on the set position of the magnetic float level gauge standpipe act to realize on-off control or alarm.

★ Electric remote transmission of liquid level gauge (optional)

Install the transmitter on the magnetic flap level gauge. The transmitter is composed of a sensor and a converter. Magnetic Float Level Gauge moves up and down through the magnetic float, and the measuring elements in the catheter move sequentially through magnetic coupling to obtain the resistance signal change and convert it into a standard current signal output of 0-10 or 4-20mA, in order to connect with digital display instruments or computers to realize remote display and control.

Magnetic Float Level Gauge Specification

| Magnetic Float Level Gauge Technical Parameter | |

| Product name | Magnetic Float Level Gauge |

| Working temperature | -40℃~350℃ |

| Working pressure | ≤4.2MPa(42Bar) |

| Medium density | 0.5-2.0g/cm3 |

| Measurement range | 0-6000mm(over 6000mm customized by requirement) |

| Accuracy | ≤±10mm |

| Installation method | Side installation, top installation, vertical installation (maximum deviation ≤ 3) |

| Connection flange caliber | DN20-DN50 |

| Flange material | SUS304,SUS316L |

| Float material | PTPE, 304 lined with PTFE, Al, Ti |

| Remote distance | 1000m |

| Protection class | IP65 |

Magnetic Float Level Gauge Working principle

The magnetic float level gauge consists of a body, a flap box (composed of red and white two-color magnetic small flaps), a float, a flange cover, and a liquid level transmitter(optional). The working principle is: the magnetic flap level gauge (also known as the magnetic float level gauge) is developed according to the principle of buoyancy and magnetic coupling. When the liquid level in the measured container rises and falls, the magnetic float in the body tube of the liquid level gauge also rises and falls, and the permanent magnet in the float is transmitted to the magnetic turning column indicator through magnetic coupling, driving the red and white turning columns to turn over 180°, when the liquid level rises, the turning column turns from white to red, when the liquid level drops, the turning column turns from red to white, the red and white junction of the indicator is the actual height of the liquid level inside the container, so as to realize the clear liquid level At the same time, the liquid level transmitter transmits the liquid level signal to the control center for liquid level indication and control, and can also be centrally monitored through the computer.

Magnetic Float Level Gauge Installation Precautions

★ No magnetic conductor is allowed around the object, otherwise it will directly affect the accurate operation of the liquid level gauge. In order not to damage the float assembly during transportation, the float assembly is taken out of the main pipe of the liquid level gauge before leaving the factory. After the liquid level gauge is installed, open the bottom drain flange and reinstall the float assembly into the main body Inside the tube, pay attention to the heavy end of the floating ball assembly facing up, and it cannot be inverted.

★ For those exceeding a certain length, it is necessary to add intermediate reinforcement flanges or ear climbers as fixed supports to increase strength and overcome its own weight; the installation position of the magnetic flap liquid level gauge should avoid or be far away from the inlet and outlet of the material medium to avoid material Rapid changes in the local area of the fluid affect the accuracy of liquid level measurement.

How to quickly get our quotation?

You need to tell me the following parameters, like this, Model and specification, medium and density, working pressure, working temperature, measurement range, connected method(flange connection is standard), configuration instrument, and other requirements. I will provide you with a quotation within half an hour.

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeters, electric control valves, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed