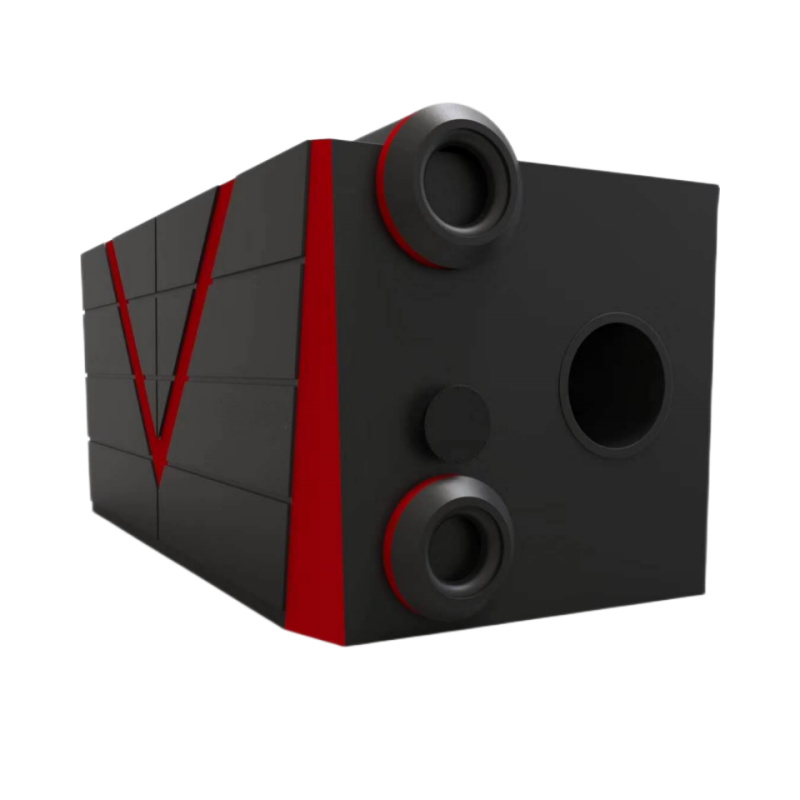

Industrial Gas Fired Double Drum Water Tube Steam Boiler

10t/h 15t/h 25t/h 30t/h natural gas steam boiler for sale

Well-sold, Cost-effective products

Features

• Automatic control operation/safety reliability/long service life

• The biggest thermal power up to 110t/h(about105,050HP)

• Application for foods & beverages, textile/chemical/petroleum/packing industry, etc.

• Rated Steam Capacity:20t/h-110t/h(about 19,100HP-105,050HP)

• Saturated Vapor: 104-225℃

superheated steam temperature:250℃、300℃、350℃、400℃、450℃

• Core Control Mode: PLC+PC control, DCS control

• Thermal Efficiency(%):>98%

Introduction

System

Reviews

Introduction of the Industrial Gas Fired Steam Boiler

Overview of the Industrial Gas Fired Steam Boiler

Industrial Gas fired steam boiler is a double-drum, horizontal, and chamber-fired D-shaped layout structure, with the furnace on the right and convection tube bundles on the left. The tail of the boiler will be equipped with energy savers according to different requirements, the energy savers include economizers, condensers, and air preheaters. The SZS steam boiler system consists of a combustion system, a control system, and a steam water system.

The industrial gas fired steam boilers series are designed to be safe, reliability, efficient,energy-saving, and environmental protection. It also features convenient maintenance, long service life, automatic intelligent control, etc. The steam boiler is widely used in large-scale projects, such as energy companies, petroleum/chemical industries, and large-scale manufacturing industries such as automobiles, wineries, food, paper, textiles, etc.

Structure of the Gas Fired Steam Boiler

The industrial gas fired boilers are double-drum, horizontal, and chamber-fired D-shaped layout structures, with the furnace on the right and convection tube bundles on the left. The upper and lower drums are fixed on the chassis of the main body through movable supports in the middle of the lower pot and at both ends and ensure that the boiler as a whole expands to both ends.

The furnace is surrounded by water-cooled walls. The water-cooled wall usually adopts a membrane wall structure. The membrane-type water-cooled wall on the left side of the furnace completely seals and separates the furnace and the convection tube bundle. The rear part of the convection tube bundle area is a sparse staggered structure (convection tube bundleⅠzone), and the front part is a sequential structure (convection tube bundleⅡzone).

Industrial Gas Fired Steam Boilers' Features

★ It adopts double drum arrangement,compact structure, and good flame fullness.

System of the Industrial Gas Fired Steam Boiler

Composition of Boiler System

·Combustion system

·Steam water system

·Control system

• Combustion system of the gas fired steam boiler

The combustion system supplies fuel to the boiler for heat generation.

Gas/Oil fired steam boilers' combustion system equips with burner and fuel device according to the fuel properties,steam capacity and pressure of the boiler.

Burner brands: Baltur, Riello, Weishaupt, Hofamat, Honeywell, Ecoflam, Cavallo and so on.

• Steam water system of the industrial gas fired steam boiler

The steam water system consists of a feedwater part and a steam part.

Feedwater part: Feedwater refers to the water that is provided to the boiler for steam conversion. The feedwater channels water into the boiler and automatically controls it to satisfy steam requirements.

Steam part: the steam is the part of the boiler responsible for collecting and regulating the steam generated by the boiler. Valves and pressure gauge controls are used to monitor and regulate steam pressure.

The steam and water system should be composed of the boiler's main body, rear heating surface(such as economizer, condenser and so on which are equipped according to the actual situation of the user), water treatment device, feedwater pump, steam header, deaerator and so on.

• Control system of the industrial gas fired steam boiler

The boiler control system is a collection of boiler electrical control components, a center for collecting and processing boiler operating signals, and an operation platform for sending execution instructions to each execution unit of the boiler.

If you want the boiler system to realize the IoT(Internet of Things) service for boiler system, we can provide you with this service when designing the control system.

The IoT system for boiler system adopts a layered structure design, namely data collection layer(M BOX), cloud platform(M SERVICE), and application layer(MYZT application system).

The control system of the industrial gas fired steam boiler provides the control of boiler water level,pressure, burning,safety protection and so on.

Control principle: Through the real-time data collection,monitoring and processing of boiler water level, pressure, flue temperature and burner, the purpose of intelligent and safe operation is achieved.

★ The Core Control Mode of the steam boiler system: PC control, PLC+PC control, DCS control. The screens of the natural gas steam boiler high efficiency is as follow:

★ Standard Control Content:boiler water level,steam pressure control,alarm and interlock,and set up an automatic control system for combustion start and stop.

★ Steam Boiler Control Modes of Operation: Automatic and Manual

a) The boiler in automatic mode is in fully automatic operation state,

b) Manual mode: The operation of the boiler equipment is controlled by manual operation. Under normal circumstances, the boiler should operate in the automatic operation state. In special cases,it will be required to switch to the manual state.

★ Control system detection data sources: burners, temperature sensors, pressure transmitters, pressure controllers, liquid level gauges, flow meters, electric regulating valves, and other remote instrument valves.

Company profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devotes to providing for customer one-step thermal energy system solutions by safety, save energy, environmental,intelligent and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers and CFB boilers), steam generator(electric steam generator, electric hot water generator), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves and so on.The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed