Industrial Boiler Control System

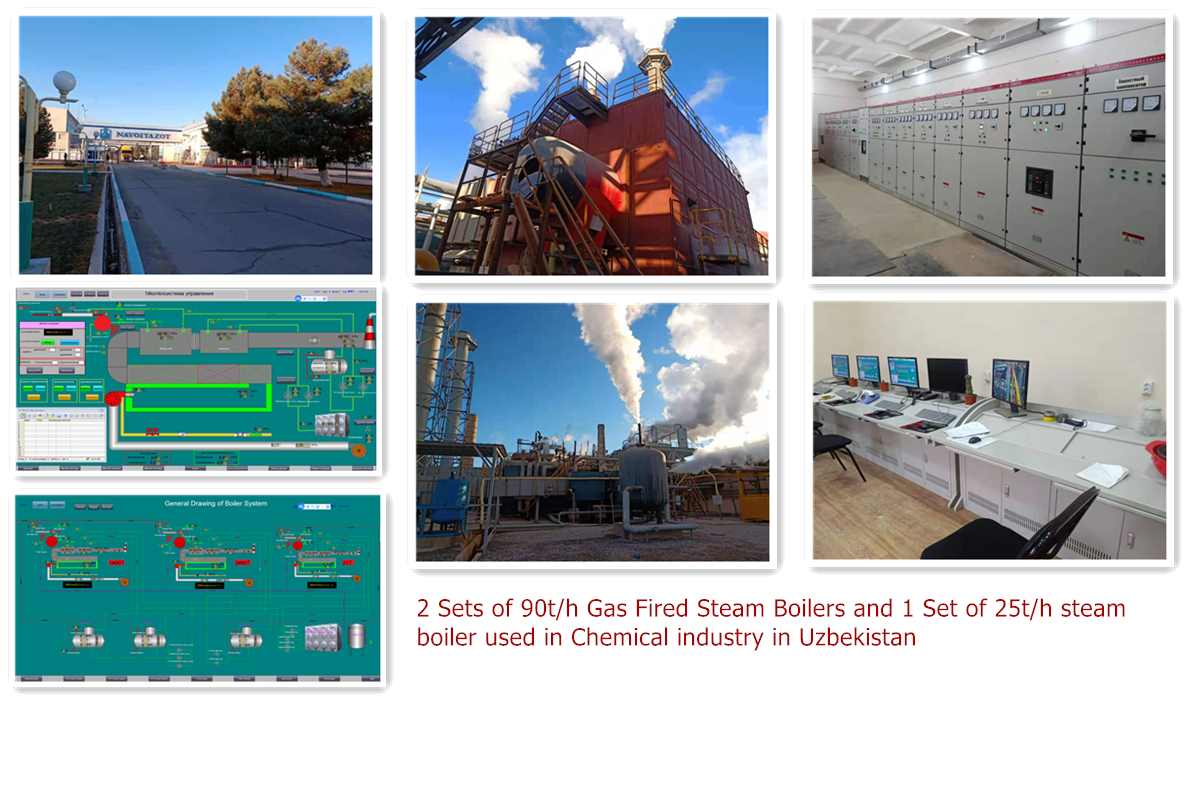

With the advancement of the times,the boiler industry is also undergoing rapid changes with the times, and the boiler control system that can make the boiler operate normally is also advancing with the advancement of science and technology.From the original single-chip button to the most used at present PLC control system,PLC+PC control system,large-scale boiler engineering project DCS control system,our company can configure cost-effective boiler equipment and provide the most optimized boiler control system according to customer needs.

At present,our existing boiler control system is suitable for oil/gas fired steam boilers, oil/gas fired hot water boilers,oil/gas fired vacuum boilers,biomass/coal fired boilers,electric heating boilers, thermal oil boilers,circulating fluidized bed boilers,etc.Heat station equipment,waste heat boiler, hot air boiler and so on.

1. Oil/Gas Fired Steam Boiler Control System

According to the customer's demand for steam capacity,temperature,pressure and equipment configuration,the steam boiler control system is developed and designed to achieve the purpose of monitoring the parameters and status of the boiler,and realize the intelligent of boiler control.

1) Main Control:liquid level control of boiler,water tank and oil tank;steam pressure control;boiler system pressure control;temperature control,etc.Manual/automatic control of burners, pump valves and other equipment,master and backup switching.Water pump start and delay shutdown, water pump running status detection and burner interlock.

2) Anti-freezing Functions:Make the boiler run safely and stably at night when unattended, and make the system work in an energy-saving state to prevent the pipeline from freezing.

3) Self-inspection Functions of the control system: continuous inspection.To alarm and interlock protection when abnormal.

4) It collects,records,saves and manages important information and data function.

The Remote Instrument Valves used in the Control System Include: temperature sensor,liquid level gauge,pressure transmitter,pressure controllers,flow meters,electric regulators,etc.

2.Oil/Gas Fired Hot Boiler Control System

Through the centralized management of the temperature of the inlet and outlet water of the boiler/heat of the main pipe, the number of boilers running, and the load status,the fully automatic operation of boiler inlet and outlet valve control, boiler start and stop, and combustion adjustment is realized.

Functions of the control system:

1) adjustment functions of the circulating water system;

2) the automatic frequency conversion feed-water function

3) functions of heat source calorimeter and thermal efficiency analysis.

4) It collects, records, saves and manages important information and data function.

The Remote Instrument Valves used in the Control System Include:temperature sensor, pressure transmitter,pressure controllers,flow meters, electric regulators, etc.

3 Sets 1.6MPa (about 232psi) of 52.5MW Gas Fired Hot Water Boiler used in thermal industry by DCS control system.

3. Oil/Gas Fired Vacuum Hot Water Boiler Control System

Main monitoring objects:burner,circulating pump, furnace vacuum,furnace water level, water tank water level,heating and hot water electric valve, etc.

No matter it is extraction method or phase change method,single heat exchange coil or multiple heat exchange coils.A variety of control algorithms to suit different vacuum boiler forms and applications.

Functions:

1) Support independent control of multiple outputs,such as domestic hot water and heating hot water.

2) Pumps,valves and other equipment are manually activated to control,the main/make-up switching.

3) One-week dual-mode timing control function,timing and temperature control at 6 time periods per day

4) Self-inspection function of the control system:continuous inspection of water level,temperature,pressure,and burner,and alarm well interlock protection when abnormal.

5)collect,record,save and manage important information and data functions about the system.

The Remote Instrument Valves used in the Control System Include:temperature sensor, pressure transmitter,pressure controllers,flow meters, electric regulators, etc.

4.Biomass/Coal Fired Steam Boiler Control System

Functions:

1) Automatically adjust the frequency of the ID fan according to the type of fuel and the amount of material to realize automatic air distribution to the boiler.

2) According to the calorific value of the fuel, the amount of materials and the energy consumption of the whole system,through the adjustment of the feeder and the grate,the boiler can be fully and efficiently burned,and the boiler load can be automatically adjusted.

3) Main control:temperature control,pressure control,liquid level control,auxiliary equipment control.

4) The automatic control terminal monitors various operating parameters of the boiler in real time.If the set safety parameters are exceeded,the automatic control terminal will alarm and interlock for protection.

5) Provide one-button start-stop and optimized control for auxiliary equipment.

The Remote Instrument Valves used in the Control System Include:temperature sensor, pressure transmitter,pressure controllers,flow meters,electric regulators,etc.

2 Sets Coal Fired Steam Boiler used in Printing Industry

5.Electric Heating Boiler Control System by PLC+PC Control

Scientifically control the input quantity and speed of heating elements according to the load conditions to achieve the purpose of precise control.Each load adjustment is an intelligent optimization process,which can effectively prevent the impact of large load input or removal of heating elements on the power grid.

Unique electric heating element life balance algorithm, undisturbed switching control of electric heating elements,prolonging the service life of electric heating elements.

Functions:

1) Temperature control,pressure control,liquid level control, antifreeze control.

2) Manual/automatic control,active/make-up switching of equipment such as pumps and valves.

3) One-week dual-mode timing control,convenient for operation and management.Timed and fixed temperature control at 6 hours a day to fully implement the peak and valley electricity price policy.

4)Self-inspection function of the control system:alarm and interlock protection for water shortage,over-temperature,over-pressure,leakage, phase loss,over-current,etc.,self-inspection for sensor failures such as temperature,pressure,liquid level,etc.Alarm and interlock protection.

5) Collect,record,save and manage important information and data about the system.

The Remote Instrument Valves used in the Control System Include:temperature sensor, pressure transmitter,pressure controllers,etc.

6.Thermal Oil Boiler Control System

It mainly detects the temperature, pressure, liquid level, differential pressure and flow of the medium in the thermal oil boiler furnace in real time. Through the safe operation optimization algorithm of the control core, it intelligently drives the peripheral actuators according to the working conditions and requirements of the equipment, so as to realize fully automatic and accurate load adjustment to achieve the best working conditions.

Functions:

1) Real-time monitoring function, when the circulating oil pump is running, when the oil temperature, flow, pressure, and pressure are different, the combustion system and the feed-oil system are interlocked, and the circulation system runs continuously to ensure safe and stable production.

2) Self-inspection function of the control system: temperature, pressure, liquid level and other sensor fault self-inspection, internal fault self-inspection of the control device, fault alarm and interlock protection.

3) Analyze the operation of the boiler.

4) Collect, record, save and manage important information and data functions about the system.

The Remote Instrument Valves used in the Control System Include:temperature sensor, pressure transmitter,pressure controllers,different pressure transmitter,etc.

4 Sets 15MW Thermal Oil Boiler used in Chemical Industry by DCS control

7.Circulation fluidized bed boiler (CFB Boiler) Control System by DCS control

Its electronic control system adopts DCS control system.Through the relationship between the control variables.The main control variable acts as the secondary control variable.During the operation of the control system,if the secondary control variable has an error,the main control variable can be compensated in time.

Control : combustion, pressure, bed temperature, air volume, liquid level and temperature control, etc.

Functions:

1) Real-time monitoring function, real-time monitoring of combustion system and steam-water system,and interlocking in case of abnormality,while the circulation system runs continuously to ensure safe and stable production.

2) Self-inspection function of the control system:temperature,pressure,liquid level and other sensor fault self-inspection,internal fault self-inspection of the control device,fault alarm and interlock protection.

3) Real-time analysis function for circulating fluidized bed boiler operation.

4) Collect,record,save and manage important information and data functions related to the system.

The Remote Instrument Valves used in the Control System Include:temperature sensor, pressure transmitter,pressure controllers,different pressure transmitter,etc.

33t/h CFB Boiler Control System by DCS control

8.Heat Exchange Station Control System

The energy-saving optimization control system of the heat exchange station adopts advanced control equipment,integrates a variety of energy-saving control strategies,and uses our own Cloud Monitoring System (Internet of Things) for monitoring.

After connecting to the system,remote guidance,real-time monitoring,remote warning, cloud analysis,online diagnosis and other functions can be performed on each independent subsystem of the heating system to realize effective telemetry and control of the heating process.

It will have a real-time and comprehensive understanding of the operating conditions of the heating system,monitor the pressure difference at unfavorable operating points,ensure the safe and reasonable operation of the district heating system,and carry out heating planning and scientific deployment according to the operating data,providing thermal power departments with accurate and valid important data.

The unified monitoring,control and interlocking protection of distributed secondary pumps, electric control valves, circulation pumps, water supply pumps, solenoid valves and other equipment in the station ensure the thermal balance of the entire heating network and the safe and reliable operation of the heating system.

The Remote Instrument Valves used in the Control System Include:temperature sensor, pressure transmitter,pressure controllers,different pressure transmitter,electric regulating valve etc.

Heat Exchange Station Control System by PLC control

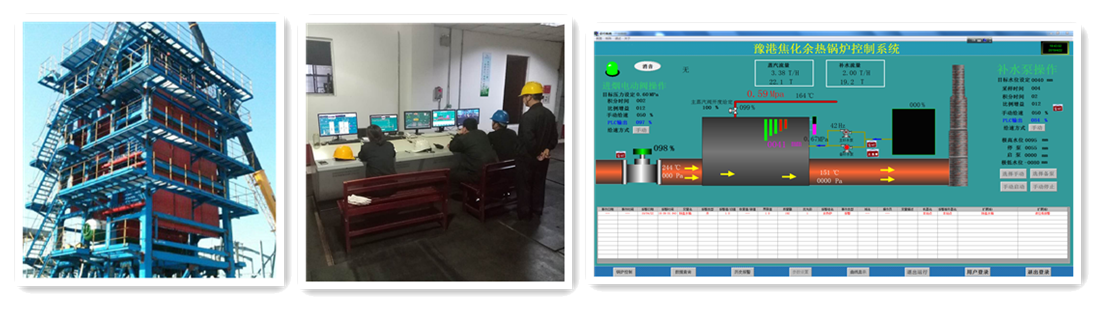

9. Waste heat boiler control system

The waste heat boiler consists of a drum, a movable hood,a flue at the furnace mouth section and other flues,a feeding pipe (feeding chute) groove, an oxygen gun mouth,a nitrogen sealing device and a nitrogen sealing plug,an inlet hole,and a differential pressure taking device,Flue support and hanger and other components.

Functions:

1) Real-time monitoring function, real-time monitoring of flue system and water system,and interlocking in case of abnormality,while the circulation system runs continuously to ensure safe and stable production.

2) Self-inspection function of the control system:temperature,pressure,liquid level and other sensor fault self-inspection,internal fault self-inspection of the control device,fault alarm and interlock protection.

3) Real-time analysis function for waste heat boiler operation.

4) Collect,record,save and manage important information and data functions related to the system.

The Remote Instrument Valves used in the Control System Include:temperature sensor, pressure transmitter,pressure controllers,liquid level gauge,etc.