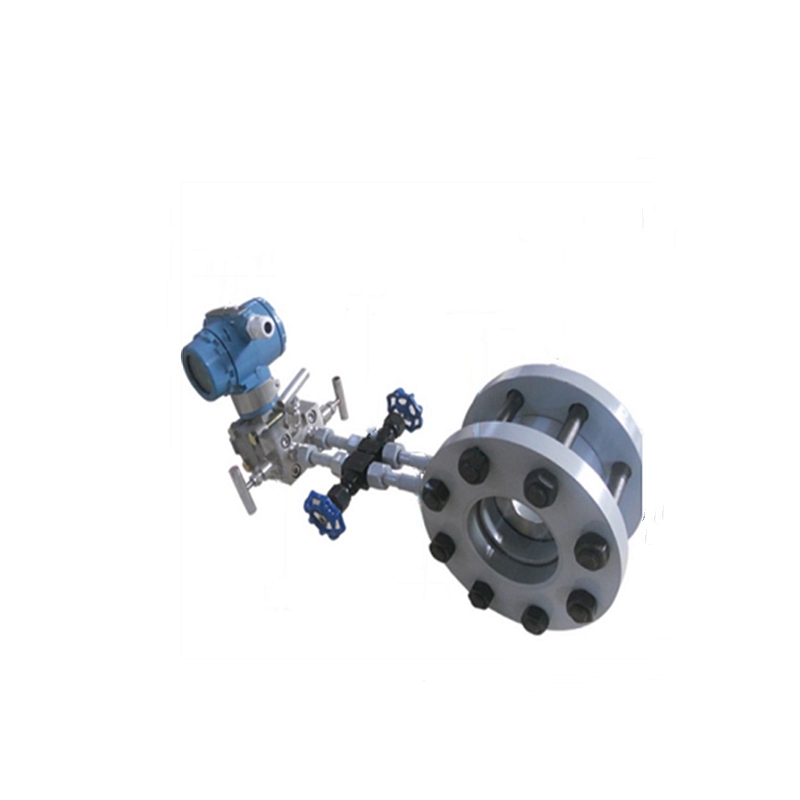

Hot Oil Flow Meter

Industrial Wafer Type Flow Meter

Measurement flow for hot oil, superheated steam, hot water on pipeline

Features

• Structure simple/Wide Application/High Stability is better than 0.1%FS/year

• Nominal diameter: DN15~DN3000

• Nominal pressure:≤40.0MPa

• Range ratio:1:10

• Accuracy class:0.5、1

• Measurement temperature range: -40°C~450°C

• Configuration: Different pressure transmitter

• Type: differential pressure flow meter

• Min. order: 1 piece

• Customization

Introduction

Reviews

Hot Oil Flow Meter Overview

A differential pressure flowmeter refers to an instrument that measures the flow rate based on the differential pressure generated by the flow detector installed in the pipeline, known fluid conditions, and the geometric dimensions of the detector and the pipeline. The hot oil flow meter belongs to differential pressure flowmeter,at the same, it is also industrial flow meter. The hot oil flow meter consists of a primary device (throttling device) and a secondary instrument (differential pressure conversion and flow display instrument). In particular, the newly emerging intelligent differential pressure transmitter is integrated with the throttling device, which not only brings great convenience and benefits to the installation, users do not need to lay installation pipelines, but also can realize automatic compensation of temperature and pressure, failure Functions such as diagnosis, very wide range, on-site range adjustment, and communication with the upper computer further expand the scope of application of the throttling device.

In the production process of petroleum, chemical industry, metallurgy, electric power, light industry, light textile, scientific research, military industry and other industries, various types of differential pressure flowmeters are still widely used for flow measurement, control and regulation. Since the differential pressure flowmeter has the advantages of simple structure, firmness, reliable operation, stable performance, moderate accuracy, and low price, its usage still occupies an absolute advantage.

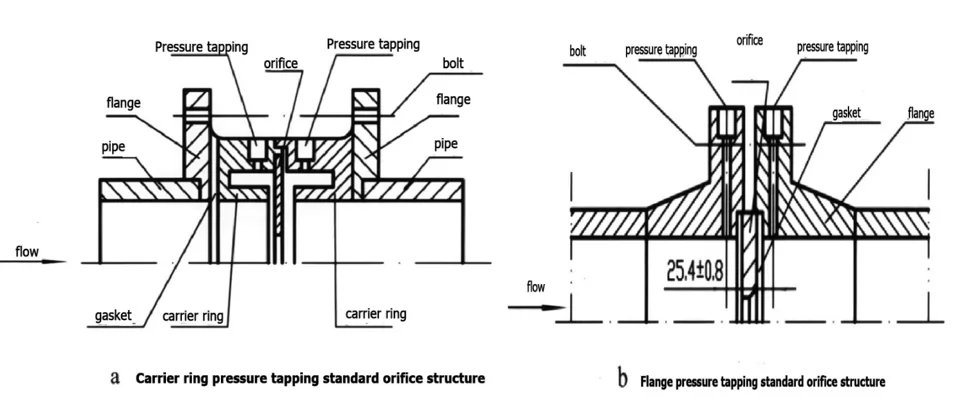

Hot Oil Flow Meter Structure

The standard orifice plate of the hot oil flow meter can be divided into three types according to the pressure taking method: corner joint pressure taking (including Carrier ring pressure tapping standard orifice structure and separate drilling pressure tapping standard orifice structure), flange pressure tapping and radial distance pressure tapping (D-D/2). Among them, radial distance pressure tapping is rarely used, please consult us for structural details.

Hot Oil Flow Meter Features

★ Standard throttles are universal and can be put into service without real flow calibration

★ Structure simple, easy copy, easy firm, performance stability, low price

★ Orifice calculation is adopted international standard

★ Wide Application: full single-phase and part mixed-phase flow can be applied.

★ Standard orifices don’t need to be calibrated and can be applied

★ Completed integral orifice plate is easy to install, it can directly Connect to the differential pressure transmitter and pressure transmitter without pressure connecting pipe.

★ It can be used for high temperatures of more than 200 °C

★ High Stability is better than 0.1%FS/year

★ High Static pressure:40MPa

★ Don’t affect by temperature and static pressure, Resistance to high overpressure

★ Continuous wokring for 5 years without any calibration

Hot Oil Flow Meter Technical parameter

| Hot Oil Flow Meter Technical Parameter | |

| Product name | Orifice flow meter |

| Measurement medium | High temperature oil, gas, superheated steam, water, hot water, saturated steam |

| Protection | IP65 |

| Caliber range | DN15~DN3000 |

| Working temperature | -40°C~450°C |

| Working pressure | ≤40.0MPa |

| Orifice plate material | SUS304/Carbon steel |

| Connection type | Flange or wafer type |

| Output signal | 4-20mA/Pulse/with Hart protocol/Modbus communication protocol |

| Application field | petroleum, chemical industry, metallurgy, electric power, light industry, light textile, scientific research, military industry and other industries, |

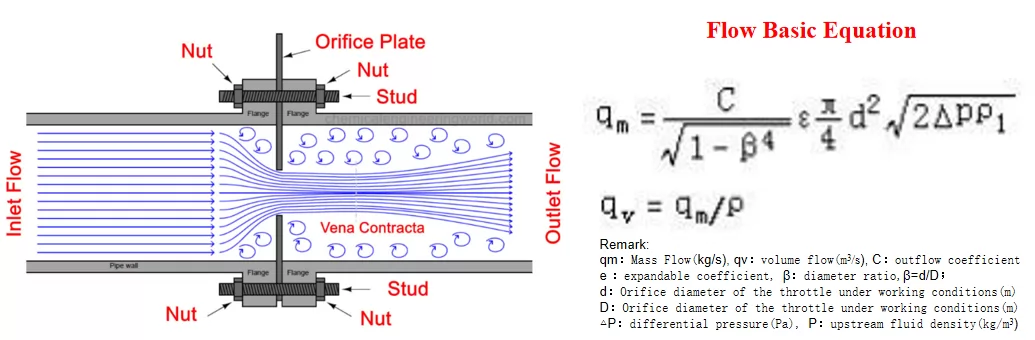

Hot Oil Flow Meter Working Principle

When the fluid filled with the pipe flows through the throttling piece in the pipe, as shown in the figure, the flow velocity will form a local contraction at the throttling piece, so the flow velocity will increase and the static pressure will decrease, so pressure will be generated before and after the throttling piece Difference. The greater the fluid flow rate, the greater the pressure difference generated, so that the flow rate can be measured in terms of the pressure difference. This measurement method is based on the flow continuity equation (law of conservation of mass) and the Bernoulli equation (law of conservation of energy). The size of the pressure difference is not only related to the flow rate but also to many other factors. For example, when the form of the throttling device or the physical properties (density, viscosity) of the fluid in the pipeline are different, the pressure difference generated under the same flow rate is also different.

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeters, electric control valves, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed