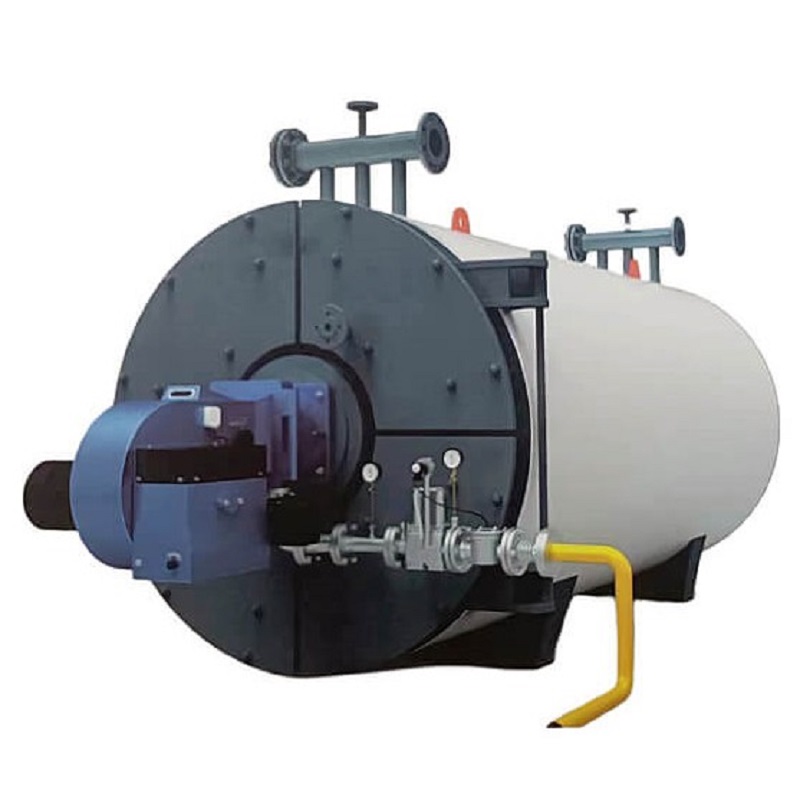

Hot Oil Boiler System

0.7MW 1.4MW 2.8MW 4.2MW 10.5MW Boiler Thermal Oil

Top selling, First choice for Chemical/Wood Processing Industry

Features

• Application for all industries, such as chemical/petroleum/wood processing industry etc.

• Round coil pipe horizontal/Back structure

• Rated thermal power: 0.7MW-14MW(930HP-18,620HP)

• Rated Work Pressure: 8bar-10bar(116psi-145psi)

• Rated outlet oil temperature: 320℃

• Core Control Mode:PLC control, PLC+PC control, DCS control

• Thermal Efficiency(%):>92%

Description

Reviews

Introduction of the Hot Oil Boiler System

Overview of the Hot Oil Boiler System

The boiler of the hot oil boiler system is a boiler that uses organic hot oil as heat medium for heat transfer. Utilizing the high-temperature characteristics of the organic heat carrier, the boiler can realize low-pressure and high-temperature heating to supply. The boiler adopts an injection type forced circulation system, and the heat exchange surface adopts square and circular tube structures.

The hot oil boiler system widely be used in petroleum, chemical industry, chemical fiber, pharmaceutical, textile printing and dyeing, light industry, building materials, wood processing, food, road construction asphalt heating and other industrial fields that require high temperature heating.

The hot oil boiler system is a special hot oil circulation system. The hot oil boiler is a special hot oil boiler developed according to the combustion characteristics of gas fuel. It can be equipped with flue gas waste heat utilization devices and auxiliary equipment such as dust removal according to customers' requirements.

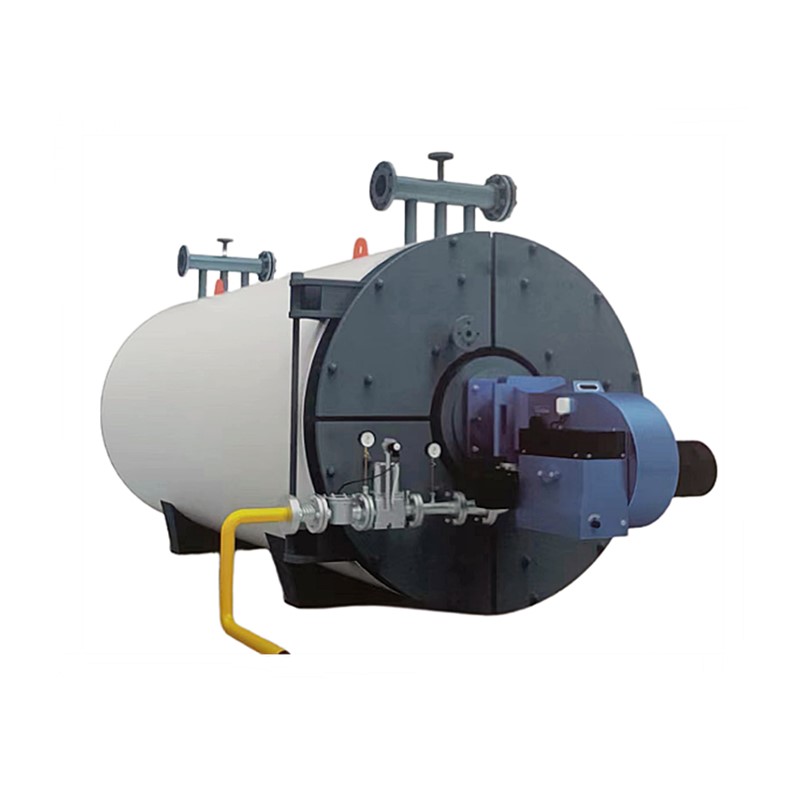

Hot Oil Boiler Body Structure

The boiler of gas fired hot oil boiler system is a round coil pipe horizontal integrated boiler. The hot oil boiler is delivered as a whole. The radiation heating surface and convection heating surface of the boiler body are both in the form of disc tubes. After it is put in place on the construction site, it can be put into operation only by connecting gas and electricity.

Hot Oil Boiler Three pass flue gas as follows:

• The first pass--furnace radiant heating surface

After the fuel is ignited and burned by the burner, the formed torch fills the coiled tube and transmits radiant heat through the coiled tube wall.

• The second pass--convective bundle area

The high-temperature flue gas generated by combustion gathers at the rear furnace door and turns to enter the second pass, that is, the convection tube bundle area. After convective heat exchange, the temperature of the flue gas gradually decreases and then reaches the front furnace door.

• The third pass--bundle area

The flue gas turns to the third pass through the front furnace door, that is, the tube bundle area, the flue gas reaches the exhaust port of the thermal oil boiler through the tube bundle area.

Remark:If the hot oil boiler system is equipped with an economizer or a waste heat boiler, it can constitute the fourth pass, and finally it is discharged to the atmosphere through the chimney.

Hot Oil Boiler features

★ The boiler is assembled, assembled, and transported to the factory. It is easy to install and saves infrastructure investment.

★ The boiler output is sufficient, and the tail of the boiler can be connected to waste heat utilization devices such as waste heat boilers, economizers, and air preheaters. The boiler efficiency is high, and the design efficiency is more than 90%;

★ The operation of the boiler can be fully automated, with automatic operation and interlock protection functions, easy to operate, and strong safety performance. The boiler is equipped with protection and interlocks such as oil temperature, smoke temperature, liquid level, flow, and pressure difference;

★ The boiler is shipped from the factory as a whole, which is convenient for transportation and a short installation period;

★ According to different burner configurations, the boiler can burn heavy oil, light oil, natural gas, liquefied gas, and other fuels, and proportional adjustment.

System of the Hot Oil Boiler

Composition of Boiler System

·Combustion system

·Medium oil system

·Control system

·Combustion system of the Hot Oil Boiler system

The combustion system in the hot oil boiler system supplies fuel to the boiler for heat generation.Hot oil boilers' combustion system equips with a burner and fuel device according to the fuel properties, steam capacity, and pressure of the boiler.

Burner brands: Baltur, Riello, Weishaupt, Hofamat, Honeywell, Ecoflam, Cavallo, and so on.

·Medium Oil System of the Hot Oil Boiler System

The medium oil system consists of injecting the oil part and circulating the oil part.

The injecting oil part: injecting oil refers to medium oil that is provided to the boiler for hot oil conversion. The injecting oil channels oil into the boiler and automatically controls it to satisfy make-up oil requirements for the system. Such as due to the high temperature oil expansion in the system, or boiler blow-down, the whole system needs fresh thermal oil to inject.

The circulating oil part: the circulating oil is part of the boiler responsible for collecting and regulating the high temperature oil generated by the boiler. Valves and pressure gauge controls are used to monitor and regulate temperature and pressure.

The medium oil system equipment consists of a boiler body, expansion tank, oil storage tank, circulating oil pump, injecting oil pump, oil gas separator, and other equipment, and oil pipelines. The heat medium oil is injected into the boiler by the circulating oil pump, and after being heated, it is transported to the heat-using equipment through the oil supply pipeline, and the heat medium oil after heat release returns to the circulating oil pump through the oil return pipeline to enter the re-circulation.

·Control System of the Hot Oil Boiler System

The hot oil boiler control system is a collection of boiler electrical control components, a center for collecting and processing boiler operating signals, and an operation platform for sending execution instructions to each execution unit of the boiler.

If you want the hot oil boiler system to realize the IoT(Internet of Things) service for boiler system, we can provide you with this service when designing the control system.

The IoT system for a hot oil boiler system adopts a layered structure design, namely data collection layer(M BOX), cloud platform(M SERVICE), and application layer(MYZT application system).

The hot oil boiler system control principle: Through the real-time data collection, monitoring and processing of boiler water level, pressure, flue temperature and burner, the purpose of intelligent and safe operation is achieved.

★The Core Control Mode of the hot oil boiler system: MCU control(Microcontroller unit), Integrated controller (All-in-one PLC, not programmable), PLC control(programmable), PLC+PC control, DCS control.

★ Standard Control Content of the hot oil boiler system: boiler level, pressure control, alarm, and interlock, and set up an automatic control system for combustion start and stop.

★ Boiler Control Modes of Operation: Automatic and Manual

a) The hot oil boiler system in automatic mode is in a fully automatic operation state,

b) Manual mode: The operation of the hot oil boiler equipment is controlled by manual operation. Under normal circumstances, the hot oil boiler system should operate in an automatic operation state. In special cases, it will be required to switch to the manual state.

★ Control system in the hot oil boiler system detection data sources: burners, temperature sensors, pressure transmitters, pressure controllers, liquid level gauges, hot oil flow meters, electric control valves, and other remote instrument valves.

Types of control cabinets for waste heat boilers: wall-mounted control cabinet, podium control cabinet, MCC vertical control cabinet, piano-style control cabinet, positive pressure explosion-proof control cabinets, and three-proof control cabinet.

Each control cabinet we leave the factory has a unique number, and it has the function of mobile phone viewing. You can see the operating status of the boiler in real-time, such as temperature, water level, pressure, alarm record, etc. But the actual operation still needs to be completed by the staff in the boiler room.

Features of control system

• Indication of operating status, with start/stop button

• Feed water pump interlock

• Scheduled startup of operation

• Display of numbers of ignition and combustion

• High temperature /high pressure/ low pressure/ antifreeze/ burner stop alarm functions

• Display of malfunctions

• Self-interlock during power down for protection

• Date/information collection, analysis, and storage function

• Password protection of controller

• Modbus RS485 interface,connection to upper control system or DCS system of the plant from multiple boilers

Company profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed