High Temperature Water Level Sensor

4 20ma Water Level Sensor

Precision measurement, High performance cost

Features

<div color:="" div="" font-family:="" font-size:="" medium="" outline:="" style="\" box-sizing:"="" temperature:=""> • Type: boiler water level sensor

Description

Reviews

High Temperature Water Level Sensor Overview

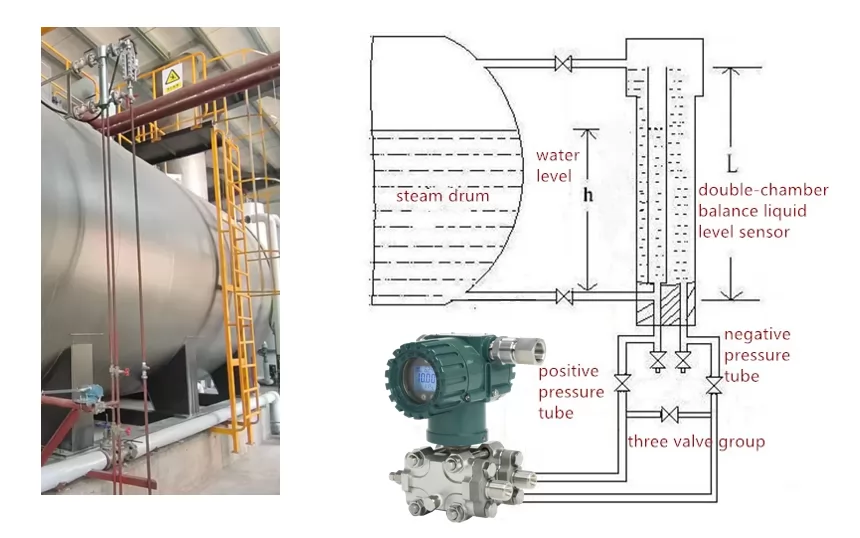

The high temperature water level sensor belongs to double-chamber balance liquid level sensor, is a steam drum water level measuring device with ingenious structure and certain self-compensation ability. There is a circular funnel structure above the reference cup to separate the entire double-chamber balance container into upper and lower parts. In order to distinguish it from the single-chamber balance container, high temperature water level sensor is called a double-chamber balance container.

The double-chamber balance vessel is mainly used to measure the water level in various pressure vessels and boiler drums. This product adopts the differential pressure measurement principle and is equipped with a differential pressure transmitter, which can accurately measure the water level in the vessel. The differential pressure transmitter by measuring the differential pressure value output by the double-chamber balance container, calculates and outputs 4-20mA analog signal.

High Temperature Water Level Sensor Technical Parameter

| High Temperature Water Level Sensor Technical Parameter | |

|---|---|

| Product name | High Temperature Water Level Sensor |

| Boiler steam drum measurement range | 300, 350, 440, 600, 670mm |

| Medium temperature | -70-580℃ |

| Medium density | ≥0.45g/cm3 |

| Medium viscosity | ≤10-m2/s |

| Accuracy | ±1mm |

| Working principle | ≤2.5MPa, ≤4MPa, ≤6.4MPa, ≤10MPa |

| Flange caliber | DN15,DN20,DN25, DN32 |

| Material | Carbon steel/stainless steel |

High Temperature Water Level Sensor Principle

The high temperature water level sensor is used together with a water level indicator or a differential pressure transmitter to monitor the water level of the steam drum during the start-up and shutdown of the boiler and under normal operating conditions, and output the differential pressure (△P) signal when the water level changes to make the boiler operate safely.

High Temperature Water Level Sensor Debugging Steps

I. When the system is not working (boiler drum liquid level is zero): on the premise of ensuring that the positive and negative pressure chambers are full of condensed water, close the balance valve, open the positive and negative phase valves, and open the vapor-liquid phase valve of the double-chamber balance container at the same time .At this time, the output should be 20mA, and the full scale. Adjust the output to 4mA on site, and make a 100% negative shift of the zero point.

II. When the system is working (boiler steam has a liquid level): on the premise of ensuring that the positive and negative pressure chambers are filled with condensed water, close the balance valve, open the positive and negative phase valves, and close the vapor-liquid phase valve of the double-chamber balance container at the same time.

III. When the measuring system is working normally, the status of the three groups of valves: the balance valve is closed; the positive and negative phase valves are open; the vapor-liquid phase valve of the double-chamber balance container is open.

High Temperature Water Level Sensor Installation and Using

★ High temperature water level sensor must be ensured that the balancing container is installed vertically.

★ The connecting pipe between the balance container and the measured container should be as short as possible, and the connecting pipe should avoid installing joints, shrinkage holes and components that affect the normal circulation of the medium.

★ The primary valve before the balance container should be installed horizontally.

★ When the drain pipe of the balance container is connected to the downpipe of the water circulation, in order to prevent the water wall and downpipe from expanding downward due to heat, an expansion joint or a "U" compensator should be installed.

★ The positive pressure chamber of the supporting differential pressure transmitter should be connected to the bottom pressure pipe of the drum, and the negative pressure chamber should be connected to the pressure pipe in the balance container. Regularly drain the differential pressure transmitter during use.

★ Under normal circumstances, the temperature of the condensing chamber is about 200°C higher than the environment, so its heat radiation ability is very strong. This causes the temperature inside the equilibrium vessel to be lower than the saturation temperature, thereby affecting the accuracy of the measurement. Therefore, the balance container and connecting pipe must be well insulated.

High Temperature Water Level Sensor Features

The high temperature water level sensor adopts a fully sealed welded structure, with diverse shapes and structures, and uses a high-temperature resistant circuit board sensor with strong anti-interference, good long-term stability, anti-lightning, anti-radio frequency interference, and high precision.

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system, etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeters, electric control valves, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed