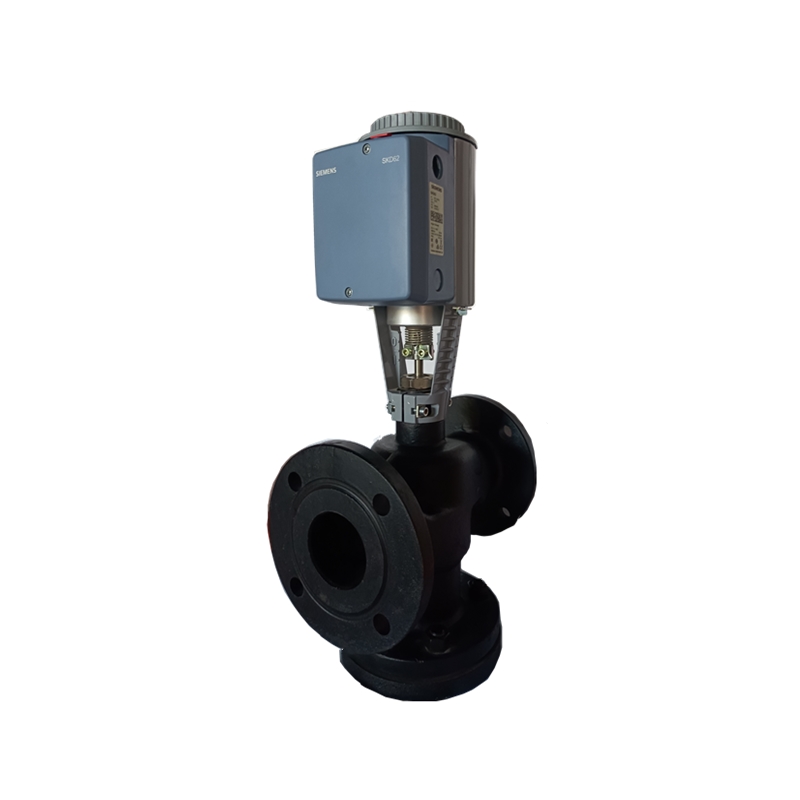

Electronic Steam Valve

Electric Regulating Valve

High stability and constant thrust

Features

• Media: Saturated steam, superheated steam, water, glycol solution, high temperature heat transfer oil, etc.

• Nominal pressure: PN16/PN25

• Valve body material: Cast steel

• Type: Electric regulating valve

<div style="\"box-sizing:" border-box;="" outline:="" none;="" color:="" rgb(0,="" 0,="" 0);="" font-family:="" roboto,="" tahoma;="" font-size:="" 15px;\"="">

Description

Reviews

Electronic Steam Valve Overview

As the degree of automation in the industrial field is getting higher and higher, the electric regulating valve is being used more and more in various industrial production fields. The electric regulating valve is an important execution unit instrument in industrial automation process control. The electronic steam valve is energy-saving and environmentally friendly, and installation is simple. The electronic steam valve is divided into three types according to the power used by the actuator, according to its function and characteristics: linear characteristics, equal percentage characteristics, and parabolic characteristics. The flow characteristic of the electric control valve is the relationship between the relative flow of the medium flowing through the electric control valve and its opening under the condition that the pressure difference across the valve remains constant. The electronic steam valve belongs to electric regulating valve. Because the actuator's structure is hydraulic, so the electric steam valve is also one kind of hydraulic electric valve.

The hydraulic electric valve actuator is a drive device that can provide linear or rotary motion, which uses a certain driving energy and works under the action of a certain control signal. The hydraulic electric valve actuator uses liquid, gas, electricity or other energy and converts it into drive action through a motor, cylinder or other device. The hydraulic electric valve actuator is used to drive the valve to the fully open or fully closed position. Some actuator used to control the valve can precisely make the valve go to any position. The electric regulating valve actuator is one kind of the electric hydraulic valve actuator,which belongs to electric control valve actuator. The electric regulating valve actuator is for the operation of 2-port and 3-port valves with a 20 mm stroke as control and safety shut-off valves in thermal oil boiler system, steam boiler system, heating, ventilation, and air conditioning plants.

Electronic Steam Valve Structure

The electric regulating valve is formed by connecting and combining the electric actuator and the regulating valve through mechanical connection assembly, debugging, and installation.

Electronic Steam Valve Technical parameter

| The valve body of electronic steam valve | |

| DN | 32-350mm |

| Route | 20mm |

| Medium | Saturated steam, superheated steam, water, glycol solution, high temperature heat transfer oil, etc. |

| PH value for medium | min 6, max 10 |

| Medium temperature | -20~350℃ |

| Nominal pressure | PN16/PN25 |

| Connection | Flange |

| Valve body material | Cast steel |

| SIMENS SKD series actuator of electronic valve | |

| Route | 20 mm |

| Positioning force | 1000 N |

| Control signal | Switch/three positions/4-20mA/0-10V |

| Voltage power | AC24V/AC230V |

| Positioning time | Open 30 s, Close 15 s |

| Spring return function | Optional |

| Protection class | IP54 |

Electronic Steam Valve Working principle

The actuator of the electronic steam valve contains a feeding function and accepts a unified 4-20mA or 1-5V·DC standard signal, converts the current signal into the corresponding linear displacement, automatically controls the opening of the regulating valve, and achieves the continuous adjustment of the process parameters such as the pressure, flow, temperature and liquid level of the fluid in the pipeline.

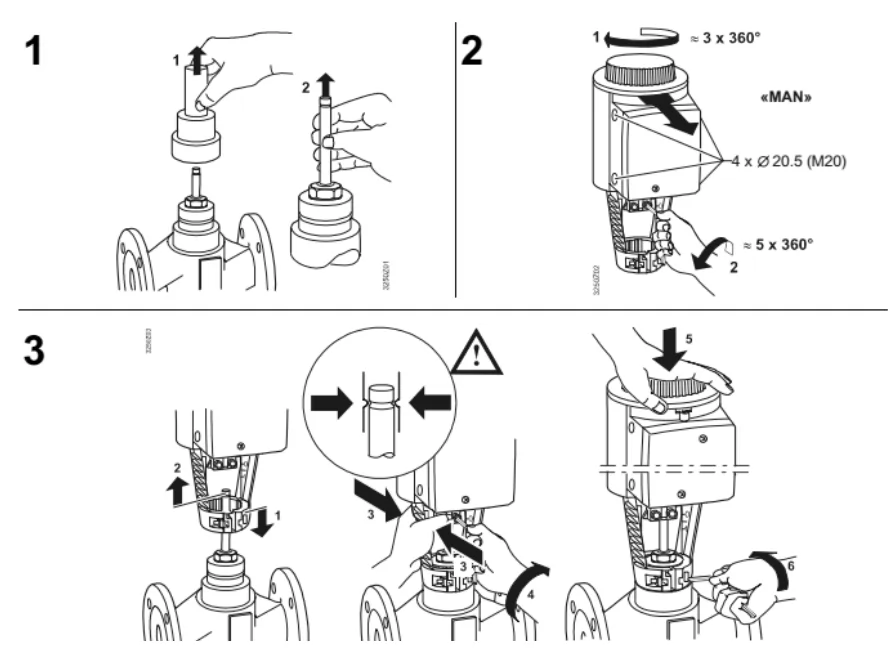

How is the Actuator Mounted on the Electronic Steam Valve Body

Electronic Steam Valve Features

• Compared with the traditional process, the valve body adopts the iron mold sand-covered casting process, and there is no expansion phenomenon. The valve body has a uniform wall thickness, non-porous trachoma, high material density, and a more refined appearance.

• The valve body and the stainless steel valve port will not be deformed after one-time molding processing in the casting process, and there will be no external leakage of the valve after long-term high-temperature use, ensuring that the valve port leaves the factory with low pressure and leakage.

• The sealing ring is made of PTFE+ carbon fiber material with better wear resistance.

• The paint surface uses a paint spraying line and drying equipment to make the paint adhesion stronger, the anti-corrosion effect better, and the gloss of the valve body significantly improved.

• High temperature resistant valve body, stable operation, and long service life.

• Integral packaging box, compensation seal, dust-proof, shock-absorbing, and smooth flow.

• High stability and constant thrust.

• The anti-deviation ability is good, the output thrust or torque is basically constant, which can well overcome the unbalanced force of the medium, and achieve accurate control of process parameters with high control precision.

• All components are installed in one housing, and all basic and advanced functions are integrated in this waterproof, dust-proof and explosion-proof enclosure.

How to Better Choose the Electric Regulating Valve

★ Electric control valves for air or other gaseous media are usually fully open spring electric control valves.

★ The electric regulating valve at the outlet of the oil production well is usually a pilot electric regulating valve.

★ The electric control valve of the steam boiler generally chooses the fully open spring electric control valve.

★ Electric regulating valves for LPG trucks or LPG railway tank cars usually use fully open built-in electric regulating valves

★ For liquid medium electric control valves, generally choose slightly open spring electric control valves.

★ If it is necessary to perform regular opening tests on the electric control valve, you should choose the electric control valve with a lifting wrench. When the medium pressure exceeds 75% of the opening pressure, you can use a lifting wrench to slightly lift the disc from the valve seat to check the opening flexibility of the electric control valve.

★ For the high-pressure bypass electric control valve of steam power generation equipment, the pilot electric control valve with dual functions of safety and regulation is usually selected.

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system, etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeters, electric control valves, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed