DCS Digital control system

Boiler DCS System Cabinet

DCS control+Advantech/Dell industrial computer

Features

· Core control hardware: DCS Control, such as Hollysys(Beijing), Xinhua(CHNT company), SUPCON(Zhejiang SUPCON), SCIYON (Nanjing)

· Industrial PC Brand: DELL industrial computer or Advantech industrial computer

· Control Cabinet: MCC Vertical Cabinet | GGD Vertical Cabinet | Piano console

· Main communication interface: Ethernet | Connect RS-485 communication interface

· Boiler capacity range: 35T/H-180T/H

· Application: SZS oil/gas boilers, coal-fired boilers, biomass boilers, and circulating fluidized bed boilers.

· Features: Reliability/Real-time/Ease of use/Openness/Economy

Description

Reviews

Overview of the DCS Digital Control System

DCS digital control system is mainly used in high-demand industrial control fields such as boiler control system, thermal energy, chemical industry, steel and building materials. In boiler control system. It is suitable for large and medium boiler systems projects, such as SZS oil/gas boilers, coal-fired boilers, biomass boilers, and circulating fluidized bed boilers, so as to realize precision control and intelligent control.

The DCS control system of the boiler is inseparable from the control of the DCS host cabinet, as well as the signal transmission and execution of the auxiliary control cabinet. Taking the DCS control system of a circulating fluidized bed boiler as an example, the corresponding control cabinets are as follows: host DCS control cabinet, low-voltage power supply inlet control cabinet, capacitor compensation cabinet, primary blower frequency conversion control cabinet, secondary blower frequency conversion control cabinet, 1# feed water pump frequency conversion control cabinet, 2# feed water pump frequency conversion cabinet, 1#-2# desulfurization and denitrification pump frequency conversion cabinet, Roots blower fan *2 and deaeration pump *2 frequency conversion control cabinet.and so on.

DCS Digital Control System Features

★ Reliability: adopt multiple redundant structures (network redundancy, controller redundancy, power supply module redundancy, I/0 module redundancy),

The system is safe, stable and reliable. The system is designed for harsh industrial environments, and the anti-interference performance meets the requirements of industrial environments international standard.

★ Real-time: The controller CPU adopts industrial-grade chips and is based on a real-time operating system to ensure accurate, real-time and efficient control.

★ Advancement: flexible structure, which not only ensures data consistency, but also load sharing; feature-rich HMI human-machine interface, flexible and powerful control software, supports offline simulation.

★ Decentralization: The intelligent design method adopted by the process I/0 unit disperses part of the control or acquisition operation to each I/0 unit to improve reliability.

★ Openness:

Open network system: Integrate Profibus-DP field bus, provide standard RS-485, RS-232, ModBUS communication protocol interface, support FF, CAN, HART, etc.

Open Operating System: Using WINDOWS

The XP operating system provides 0DBC and 0PC interfaces and supports Internet access.

★ Economy: The system design of the field bus can effectively save the overall project investment and reduce operation and maintenance costs.

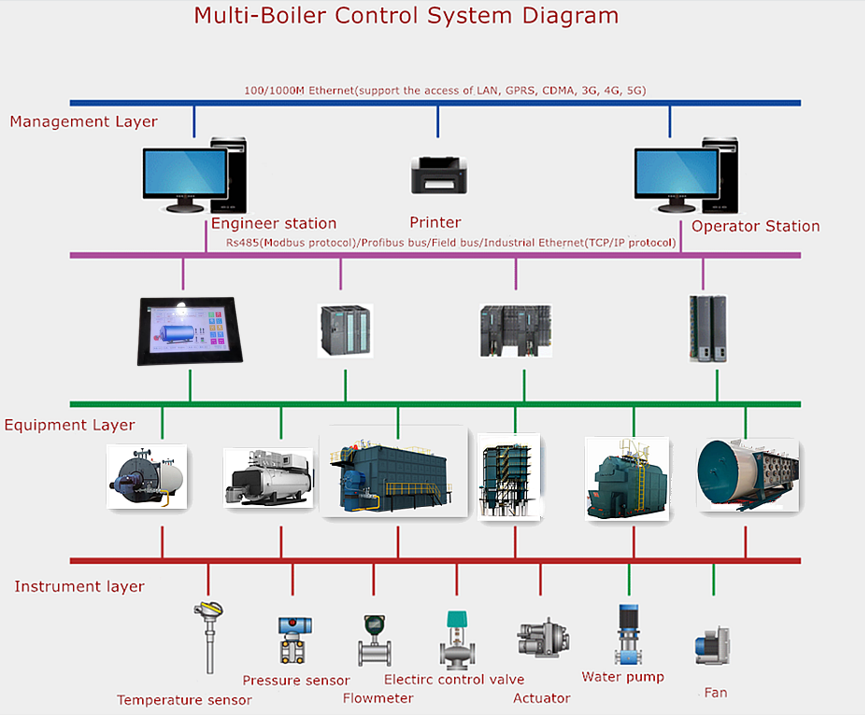

Boiler DCS Digital Control System Structure

The boiler DCS digital control system structure is composed of engineer station, operator station, history station server station (optional), field control station components.

· Engineer station: used to complete system configuration, modification and downloading, including: database, graphics, control algorithm, report configuration, parameter configuration, operator station, field control station and process I/0 module configuration configuration , data download and incremental download, etc.

· Operator station: used for monitoring and management of boiler status, including: centralized management and monitoring of boiler system data, boiler flow chart display, report printing, control operation, historical trend display, log, alarm record and management, etc.

· On-site control station: It is used to complete on-site signal acquisition such as remote instrument valve signal acquisition, boiler system control and interlock control algorithm, control output, and transmit data and diagnostic results to the operator station through the system network

· Server station: used to complete system historical data service (optional configuration)

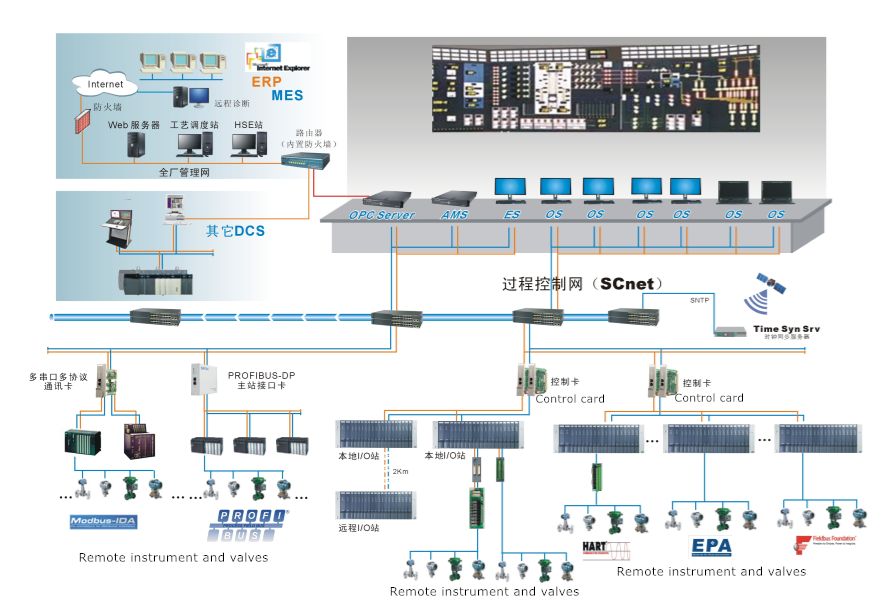

Boiler DCS Digital Control System Network Structure

The DCS digital control system network structure consists of three parts, management network (MNET), system network (SNET), and control network (CNET). Among them: the system network and the control network are redundant configurations, and the management network is an optional network.

· Management Network (MNET): realizes advanced management and sharing of data. Composed of 100/1000M Ethernet, it is used for communication between the control system server and the plant-level information management system (REALMis or ERP), INTERNET, and third-party management software.

· System network (SNET): It is composed of 100/1000M high-speed redundant industrial Ethernet network, which is used for the connection of engineer station, operation station, field control station and communication control station, and completes the data downloading of field control station. A high-speed redundant safety network that can quickly build a star, ring or bus topology.

· Control network (CNET): It adopts field bus to connect with various I/O modules and intelligent devices, completes process or field communication tasks in real time, quickly and efficiently, and complies with IEC61158 international standard (national standard: JB/T10308.3-2001/European standard : EN50170), the transmission medium is shielded twisted pair or optical cable.

Company profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeter, electric control valve, Zirconia, TDS sewage, and so on.

CN Boiler has always adhered to the concept of electrical full integration in the industrial energy industry, that is, integrating strong and weak current systems such as boiler control, boiler room auxiliary machine control, upper monitoring system, and boiler room power distribution system into a complete electrical package, forming a characteristic industrial energy control system (CN Boiler Multi-Boiler Control System, referred to as CN Boiler- MBCS).

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed