Capacitive Fluid Level Sensor

Non Contact Capacitive Level Sensor

With buffer structure, it can effectively prevent boiler water from tumbling

Features

• high temperature resistance/high pressure resistance/corrosion resistance/fluctuation resistance

• With buffer structure, it can effectively prevent boiler water from tumbling

• Measurement of industrial process quantifiers including liquid level

• Bear pressure: 0~1.6MPa(16Bar),Max 1.6MPA

• Output: 4-20mA

• Measurement period: 0.1s

• Medium temperature: ≤200℃

• Type

Introduction

Reviews

Capacitive Fluid Level Sensor Overview

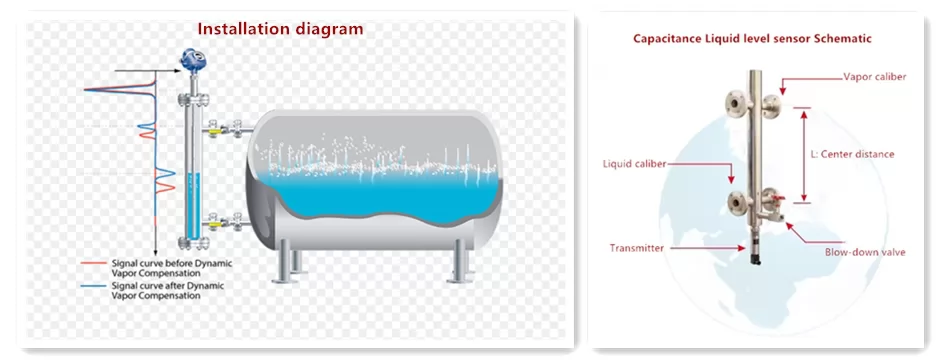

The capacitive fluid level sensor is an economical boiler level gauge designed for small and medium boilers. Based on radio frequency capacitance measurement technology, the capacitive fluid level sensor outputs a 4-20mA continuous standard signal, which is used for precise measurement and control of small boiler drum liquid level. The capacitive fluid level sensor can change the medium or change the installation environment at any time, and can automatically adapt without recalibration, and measure accurately without being affected by medium changes. The capacitive fluid level sensor can measure without contact, so it is called non contact capacitive level sensor.

The capacitive fluid level sensor integrates the performance of high temperature resistance, high pressure resistance, corrosion resistance, and fluctuation resistance. The transmission part uses military components to make the signal output more stable and reliable. The capacitive fluid level sensor is easy to install, has less maintenance, accurate measurement and control, high cost performance, and has a buffer structure, which can effectively prevent the boiler water level from churning. It is an ideal replacement product for the traditional electrode type and magnetic flap type liquid level gauge.

_1688983926_WNo_800d320.webp)

The capacitive fluid level sensor has the advantages of simple structure, high resolution, reliable operation, fast dynamic response, non-contact measurement, and can work under harsh conditions such as high temperature, radiation, strong vibration, etc. Capacitive fluid level sensor has been widely used in various fields of industrial and agricultural production.

Capacitive Fluid Level Sensor Features

★ With a buffer structure, the capacitive fluid level sensor can effectively prevent boiler water from tumbling

★ The steam condensing structure can maximize the consistency of the temperature of the capacitive fluid level sensor and the boiler drum body to ensure the real measurement of the water level; the capacitive fluid level sensor can effectively realize the separation of steam and water, and prevent the surface of the capacitive sensor from hanging water; it can avoid water and steam on the capacitive sensor shock

★ Inverted structure, automatic sealing, to ensure the safety and reliability of the electrical part

★ There is no need to observe the water level to adjust the zero and full points, the capacitive fluid level sensor automatically recognizes

★ Optional HART protocol, which can be equipped with an on-site display

Capacitive Fluid Level Sensor Specification

| Capacitive Fluid Level Sensor Technical Parameter | |

| Product name | capacitive fluid level sensor |

| Medium temperature | ≤200℃ |

| Protection class | IP65 |

| Connection type | Flange,or customized by requirement |

| Center distance | Customized by requirement |

| Bear pressure | 0~1.6MPa(16Bar) |

| Output signal | Resistance signal |

| Supply power | Max: 28V, Min: 20V |

| Current loop | two-wire system 4.0mA~20mA(+-2.5%) |

| Measurement range | ≤600mm |

| Measurement period | 0.1s |

| Environment temperature | -40℃~85℃ |

| Protection class | IP65 |

| Explosion proof class | Exia IIC T6 Ga(customized) |

| Explosion-proof parameter: | Ui=28VDC,Ii=93mA,Pi=0.65W,Ci=0.02uf,Li=0.1mH |

Capacitive Fluid Level Sensor Principle

The capacitive fluid level sensor products are based on radio frequency capacitance measurement technology, outputting a 4-20mA continuous standard signal. It has the advantages of simple structure, high resolution, reliable operation, fast dynamic response, non-contact measurement, and can work under harsh conditions such as high temperature, radiation, strong vibration, etc. It has been used in various fields of industrial and agricultural production.

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeters, electric control valves, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed