Boiler Control Unit

PLC&PC Boiler Panel Control

Siemens Simatic Series PLC+Advantech/Dell industrial computer

Features

· Core control hardware: Programmable Siemens PLC, such as S7-200Smart, SIMATIC S7-300, SIMATIC S7-1200, SIMATIC S7-1500, SIMATIC S7-400

· Industrial PC Brand: DELL industrial computer or Advantech industrial computer

· HMI(Human Machine Interface): 10.1-inch true color touch screen (7-inch optional)

· Control product appearance: Wall-mounted Cabinet | Podium Cabinet | MCC Vertical Cabinet | GGD Vertical Cabinet | Piano console

· Main communication interface: Ethernet | Connect RS-485 communication interface

· Boiler capacity range: 20T/H-50T/H

· Application: oil fired boiler, gas fired boiler, coal fired boiler, biomass fired boiler, electric boiler, waste heat boiler, CFB boiler and so on.

Description

Reviews

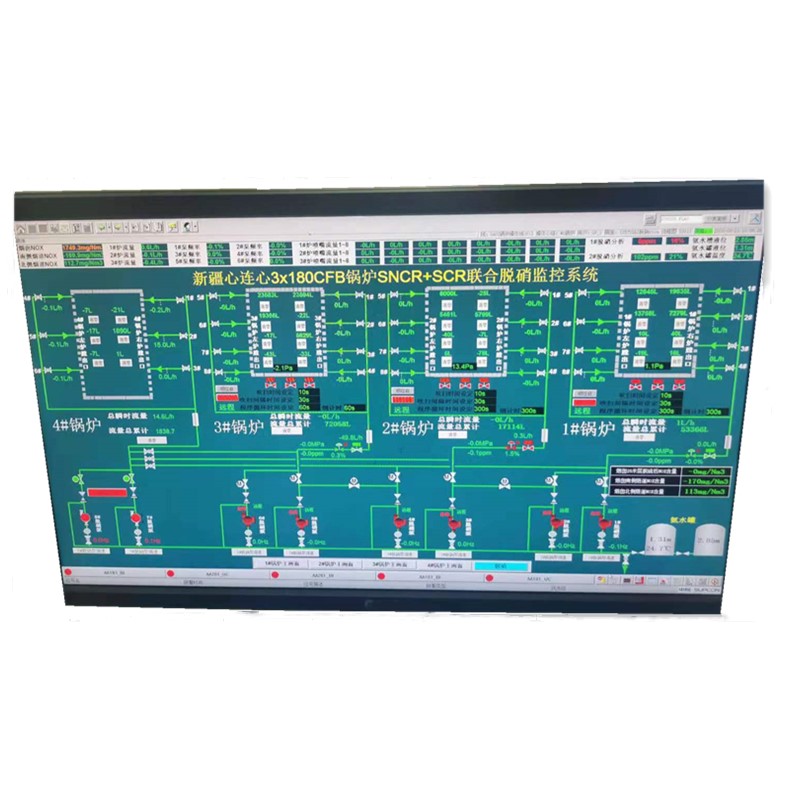

Overview of the PLC&PC Boiler Control Unit

The boiler control unit is composed of the PLC&PC control,it can be used for various boilers control system. The plc brand is Siemens and programmable, such as SIMATIC S7-200Smart, SIMATIC S7-300, SIMATIC S7-1200, SIMATIC S7-1500, SIMATIC S7-400. The PC brand is the DELL industrial computer or Advantech industrial computer. A programmable logic controller (PLC) is a digital computer used for the automation with ability to re-programmed the logic as per the requirements of users in industries. Relying on the experience of many technicians in the control of industrial boilers, the boiler plc control system is designed according to industrial standards for the special use environment of boilers, with high anti-interference performance. According to the special needs of customers, we can research and develop boiler plc control systems that meet industrial standards and meet customer requirements, so as to realize the intelligence of the control system.

The smart choice for automation: SIMATIC PLC controllers

Based on PLC or PC, SIMATIC controllers are powerful, compact, and modular, and can be installed in the control cabinet or directly on the machine. No matter what the application, there is always a suitable controller to choose from. According to the specific requirements of users, We equip Siemens SIMATIC control with the right solution for the boiler PLC control system. They enable consistent, powerful, and efficient automation engineering in a way typical of SIMATIC controllers in boiler PLC control systems.

We have many kinds of PLC control cabinets, such as wall-mounted cabinets, podium cabinets, MCC vertical cabinets, GGD vertical cabinets, and piano consoles. We generally configure different forms of control cabinets according to the number of boiler system detection points and the capacity of the boiler. Generally, we configure integrated PLC control cabinets including water pump control, and fan control below 6 ton/h steam boiler, and configure more than three control cabinets above 6 ton/h boilers, such as control cabinet fan, pump control cabinet, PLC control cabinet, sometimes, the power control cabinet also be optional.

PLC&PC Boiler Control Unit Working Priciple

PLC programming is widely used, powerful and easy to use, and has become one of the main devices of contemporary industrial automation. PLC and the host computer communicate with each other, the command issued by the host computer will be first given to the PLC, and then the PLC will be interpreted as the corresponding timing signal, directly control the corresponding PLC equipment. Sometimes, the PLC reads the status data of the device and converts it into a digital signal to feed back to the upper computer. The PLC+PC control system adopts a distributed control system. The PLC independently controls the field controlled equipment, and the upper computer manages and monitors each PLC. At the same time, it forms an independent operating system with the PLC, which will not affect the operation of each other.

PLC&PC Boiler Control Unit Technical Features

★ Industrial PC features

The chassis adopts steel structure, which has high anti-magnetic, dust-proof and impact-proof capabilities.

There is a dedicated backplane inside the chassis, and there are PCI and ISA slots on the backplane.

There is a special power supply in the chassis, and the power supply has strong anti-interference ability.

Ability to work continuously for a long time is required.

★ communication module

Support PROFIBUS master-slave communication, RS485 and RS232 communication modules provide connection and I/O for point-to-point serial communication connect to the master

★ Simple remote control application

The communication processor CP 1242-7 can be connected via a simple HUB (hub) or mobile phone, Network or Internet (Internet) to simultaneously monitor and control distributed.

★ Integrated PROFINET interface

The integrated PROFINET interface is used for programming, HMI communication and communication between PLCs.

★ Integrated process

high speed input

The controller has multiple high-speed counters, the main body supports a maximum of 100 kHz, and the signal board supports a maximum of 200 kHz for counting and measurement.

high speed output

The controller integrates high-speed pulse outputs for speed and position control of stepper motors or servo drives.

★ Memory

Provides up to 150 KB of shared working memory for user instructions and data. Also provides up to 4 MB of integrated load memory and 14 KB of retentive memory.

The SIMATIC memory card is optional and can be used as a programming card, transfer card and firmware update card through different settings. It allows easy transfer of programs to several CPUs. The card can also be used to store various files or update the firmware of the controller system.

★ Intelligent Device

Through simple configuration, the PLC controller can be configured as a Profnet IO intelligent device, and realize the distributed IO application of the master-slave architecture with the IO controller.

★ Expandable and flexible signal board design

One signal board can be connected to all CPUs, allowing you to tailor the CPU by adding digital or analog input/output channels to the controller without changing its size.

The Relationship Between PLC and PC in Boiler Control Unit

Different sensors and field devices are used to measure critical parameters such as water flow, steam flow rate, and water level. PC visuals are used to monitor the parameters, and PLC is used to control the operation. If the feed water flow rate, water level, and steam flow exceed the predefined value, then the entire setup will shut down and automatic check valves are opened to release the steam and pressure.

Company profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeter, electric control valve, Zirconia, TDS sewage, and so on.

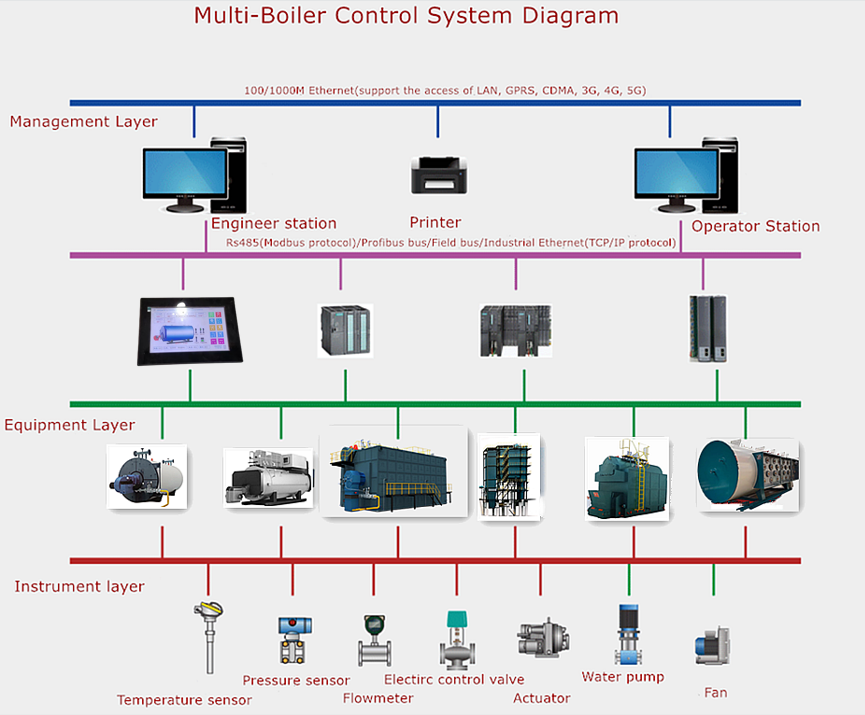

CN Boiler has always adhered to the concept of electrical full integration in the industrial energy industry, that is, integrating strong and weak current systems such as boiler control, boiler room auxiliary machine control, upper monitoring system, and boiler room power distribution system into a complete electrical package, forming a characteristic industrial energy control system (CN Boiler Multi-Boiler Control System, referred to as CN Boiler- MBCS).

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed