24v Valve Actuator

Electric Hydraulic Valve Actuator

Precision control, High performance cost

Features

• Media: Water, Thermal oil, Steam

• Place of Origin: Germany

• Brand: SIMENS

• Type: Electric control valve actuator

<div style="\"box-sizing:" border-box;="" outline:="" none;="" color:="" rgb(0,="" 0,="" 0);="" font-family:="" roboto,="" tahoma;="" font-size:="" 15px;\"="">

Promise

Description

Reviews

24v Valve Actuator Overview

The electric control valve actuator is a drive device that can provide linear or rotary motion, which uses a certain driving energy and works under the action of a certain control signal. The electric control valve actuator uses liquid, gas, electricity or other energy and converts it into drive action through a motor, cylinder or other device. The 24v valve actuator is used to drive the valve to the fully open or fully closed position. Some actuator used to control the valve can precisely make the valve go to any position. The 24v valve actuator is one kind of the electric hydraulic valve actuator,which belongs to electric control valve actuator.

SKD62 Electro-hydraulic actuator, 1000 N, 20 mm, AC 24 V, DC 0...10 V/4...20 mA, spring return

With fail-safe function.

Overload-proof through travel-dependent, electronic switching off in end position.

With die-cast aluminium housing and yoke for valves with 20 mm stroke.

Optional function with one auxiliary switch.

With manual control.

For the operation of 2-port and 3-port valves with a 20 mm stroke as control and safety shut-off valves in thermal oil boiler system, steam boiler system, heating, ventilation, and air conditioning plants.

24v Valve Actuator Technical parameter

| 24V Valve Actuator Technical Parameter | |

| Type | Ball Valves, Gate Valves, Solenoid Valves |

| Place of Origin | Germany |

| Brand Name | Simens |

| Model Number | SKD60/SKD62 |

| Application | General |

| Temperature of Media | High Temperature, Low Temperature, Medium Temperature |

| Power | Electric |

| Media | Water, Thermal oil, Steam |

| Port Size | DN15-DN250 |

| Structure | Control |

| Operating voltage | AC 24 V |

| Positioning signal | DC 0...10 V, DC 4...20 mA, 0...1000 Ohm |

| Power consumption | 10 VA |

| Positioning force | 1000 N |

| Positioning time | Open 30 s, Close 15 s |

| Stroke | 20 mm |

| Spring return function | No |

| Position feedback | DC 0...10 V, DC 4...20 mA |

| Degree of protection | IP54 |

| Medium temperature | -25...320 °C |

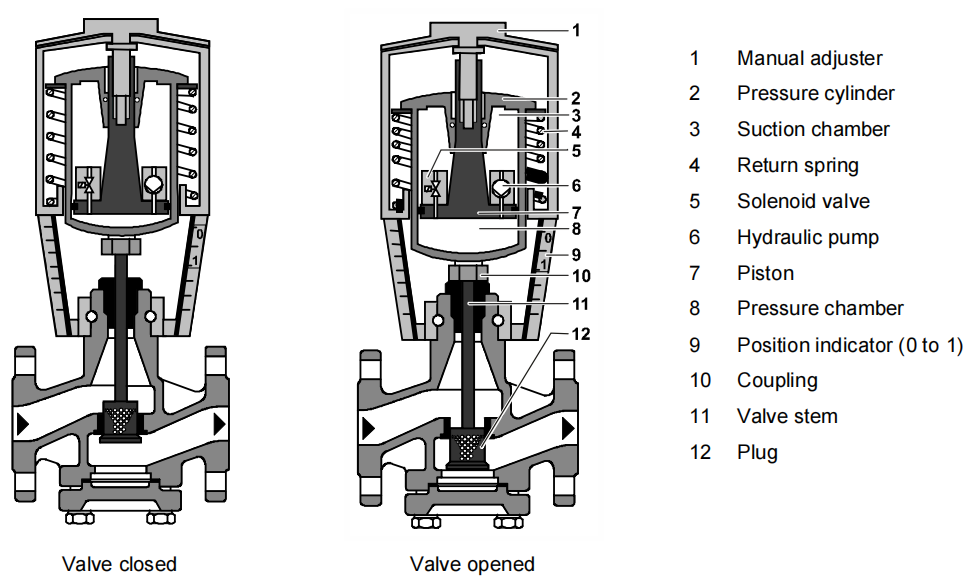

24v Valve Actuator Principle

★ Opening the valve

The hydraulic pump [6] forces oil from the suction chamber [3] to the pressure chamber [8], thereby moving the pressure cylinder [2] downwards.The valve stem [11] retracts and the valve opens. Simultaneously, the return spring [4] is compressed.

★ Closing the valve

Activating the solenoid valve [5] allows the oil in the pressure chamber to flow back into the suction chamber. The compressed return spring moves the pressure cylinder upwards. The valve stem extends and the valve closes.

★ Manual operation mode

Turning the manual adjuster [1] clockwise moves the pressure cylinder downwards and opens the valve. Simultaneously, the return spring [4] is compressed.

In the manual operation mode, the positioning signals Y and Z can further open the valve but cannot move to the 0 % stroke position of the valve. To retain the manually set position, switch off the power supply or disconnect the positioning signals Y and Z. The red indicator marked “MAN” is visible.

Note: When setting the controller to manual operation for a longer period of time, we recommend adjusting the actuator with the manual adjuster to the desired position. This guarantees that the actuator remains in this position for that period of time.

Attention: Do not forget to switch back to automatic operation after the controller is set back to automatic control.

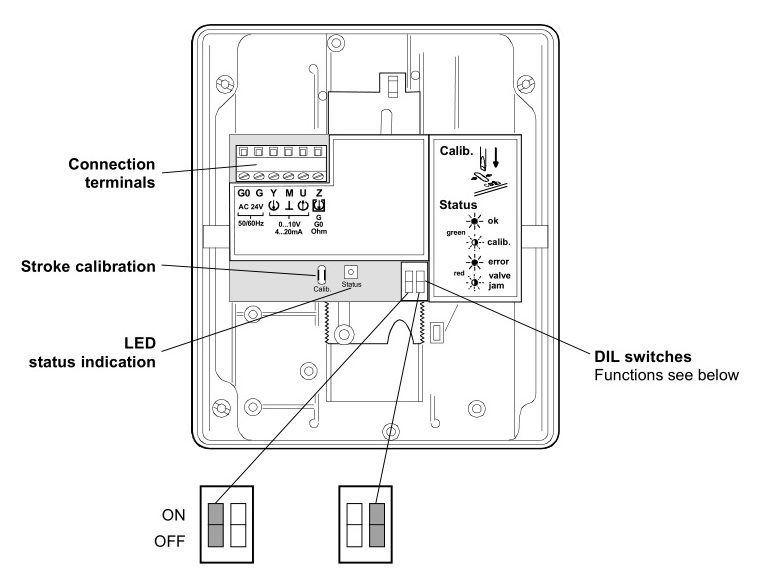

24v Valve Actuator Standard Electronics

24v Valve Actuator Features

·High stability and constant thrust.

·The anti-deviation ability is good, the output thrust or torque is basically constant, which can well overcome the unbalanced force of the medium, and achieve accurate control of process parameters with high control precision.

·All components are installed in one housing, and all basic and advanced functions are integrated in this waterproof, dust-proof and explosion-proof enclosure.

·The disadvantage is that when the power fails, the valve can only stay in place, and only with the backup power system, the valve can achieve the fail-safe position (fail open or fail closed).

How to choose electric control valve actuator

·Driving energy

The most commonly used driving energy is power or fluid source. If power is selected as the driving energy, three-phase power is generally used for large-sized valves, and single-phase power is used for small-sized valves. General electric actuators can have a variety of power supply types to choose from.

·Valve type

When choosing an actuator for a valve, it is necessary to know the type of valve so that the correct type of actuator can be selected. Some valves require multi-turn drives, some require single-turn drives, and some require reciprocating drives, which affect the choice of actuator type.

·Moment size

For valves with a 90-degree rotation such as: ball valves, disc valves, and plug valves, it is best to obtain the corresponding valve torque from the valve manufacturer.

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves, and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system, etc. The remote instrument and valves include temperature sensors, pressure transmitters, pressure sensors, pressure controllers, liquid level meters, flowmeters, electric control valves, Zirconia, TDS sewage, and so on.

Share your thoughts

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed