Featured Products

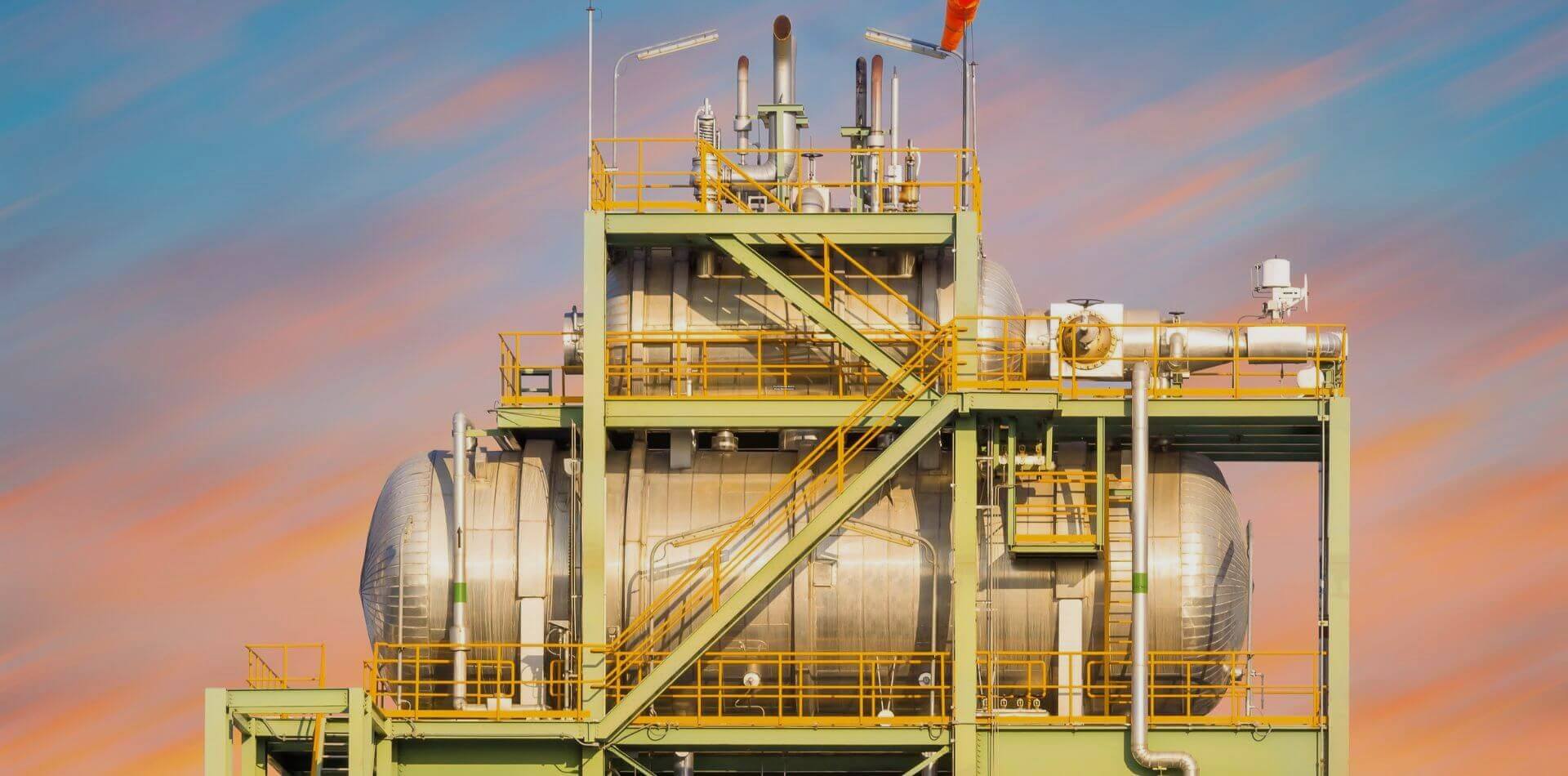

CN Boiler mainly provides high-quality industrial boilers, steam generators, heat exchangers, instruments, and so on.

Industrial Boiler Manufacturer

26 Years of Experience

We have unparalleled professional advantages in equipment selection, control system R&D, manufacturing and maintenance, and our practice of innovation and reliability has been recognized by our customers. We start from meeting customer needs, and practice to provide customized solutions to meet customer needs.

Industrial Boiler Manufacturer

26 Years of Experience

We have unparalleled professional advantages in equipment selection, control system R&D, manufacturing and maintenance, and our practice of innovation and reliability has been recognized by our customers. We start from meeting customer needs, and practice to provide customized solutions to meet customer needs.

Boiler Control Panels Manufacturer in China

26 years of R&D and practice without change.

Intelligent control involves the safety, convenience, energy saving and high efficiency of the boiler system. With 26 years of experience in industrial boiler control, it is designed and manufactured according to industrial standards for the special use environment of boilers, with high anti-interference performance. We have not only HMI+PLC control panel, but also PLC control, PLC+PC control and DCS control that can be edited and developed according to the actual situation of customers.

Our Projects

The application of our company's products and the fields of EPC project operation and implementation include many industries, including heat, energy, petroleum, electric power, the chemical industry, hotels, and large-scale industrial projects.

Learn About More Projects

Latest

ReadMore >>

11

Mar

What Are the Common Problems or Failures Encountered with Magnetic Float Level Gauges, and How Can They Be Prevented?

Magnetic float level gauges are generally very reliable devices, but like any equipment, they can experience issues over time or in challenging conditions. Common problems usually relate to the float’s movement, the indicator’s behavior, or mechanical integrity. Understanding these typical failure modes and their causes is important so that users can take preventive measures and address issues promptly. Here CN Boiler will discuss several common problems/failures with magnetic level gauges and how to prevent or troubleshoot them, such as Float Sticking or Binding, Indicator Misreads or Erratic Movement, Bridging or Clogging in High-Viscosity Fluids, External Leakage or Seal Failure and Preventive Maintenance Measures.11

Mar

How do I Select the Appropriate Magnetic Float Level Gauge for My Specific Application?

Selecting the right magnetic float level gauge for a specific application involves considering several factors – from process conditions like pressure, temperature, and fluid properties, to practical aspects like installation constraints and compliance with standards. A magnetic level gauge must be tailored (often custom-fabricated) to ensure the float and chamber will function reliably under your conditions. Below CN Boiler outlines a systematic approach to selecting an appropriate gauge, highlighting key considerations and best practices. By understanding your application's requirements and the gauge's capabilities, you can choose a magnetic level indicator that provides accurate readings, longevity, and safety. CN Boiler explains from key factors to consider in selection to selection process in practice in order to introduce how to select the magnetic float level gauge in the article.11

Mar

What Are the Advantages of Using Magnetic Float Level Gauges Compared to Other Measurement Methods?

Magnetic float level gauges (also known as magnetic level indicators) offer several distinct advantages over other level measurement methods. In industrial practice, level can be measured by methods ranging from simple sight glasses to sophisticated radar transmitters. Each technology has its pros and cons. Here CN Boiler focuses on the key advantages of magnetic float level gauges and how they compare to alternatives like sight glass gauges, differential pressure transmitters, radar/ultrasonic sensors, and others. Overall, magnetic gauges are valued for their safety, clarity of indication, and reliability in demanding applications. CN Boiler will explain the advantages of the magnetic float level gauges compared to other measurement methods from a professional perspective.10

Mar

What are the main components of a magnetic float level gauge?

CN Boiler will do the conclusion, a magnetic float level gauge is composed of a float with a magnet (the moving sensor element), a chamber that interfaces with the process fluid, an external indicator (flags or follower) that visually displays the level, and the necessary connections and mounting hardware to attach it to a vessel. The synergy of these components yields a level gauge that is robust, self-contained, and easy to read, bridging the internal process conditions to an external, safe indication through magnetic coupling. Understanding each part – float, chamber, indicator, magnets, and accessories – helps in selecting the right configuration and caring for the gauge to ensure long-term accurate service.Provide the Best Quality Boilers and Boiler Accessories!